5 Steps for Dry-Process Electrode Preparation

In the process of preparing electrode sheets, there exists a relatively niche method—dry electrode preparation. This technique is suitable for carbon materials with large specific surface areas and those requiring in-situ XRD testing. This article will detail the laboratory method for preparing dry electrodes for educational and collaborative purposes.

Step 1 – Mixing Dry Powder

Weigh the sample and conductive carbon black in a specified ratio (recommended 40 mg : 5 mg) and thoroughly mix them in an agate mortar. Scrape the powder adhering to the mortar walls multiple times during mixing. It is crucial to ensure complete mixing, as inadequate mixing will adversely affect the subsequent film rolling step.

Step 2 – Weighing the Binder

Place the small Petri dish on the balance. Add the pre-measured volume of PTFE solution (17.6% solid content aqueous suspension), followed by two drops of ethanol. Then pour in the pre-mixed dry powder.

Step 3 – Mixing the Slurry

Stir the powder poured into the glassware in the previous step. The paste may initially be quite thin, but as the ethanol evaporates, it will eventually dry out. You may add a few drops of ethanol until it forms a relatively moist small lump.

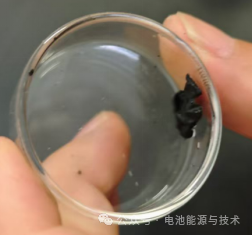

Step 4 – Film Rolling

Transfer the small ball from the previous step onto the glass plate. Use a glass rod to repeatedly press and roll it, continuously adding ethanol drop by drop throughout the process. Fold the membrane repeatedly until a relatively flexible film forms on the glass plate. This step is the most complex in dry electrode preparation, requiring patience and multiple attempts.

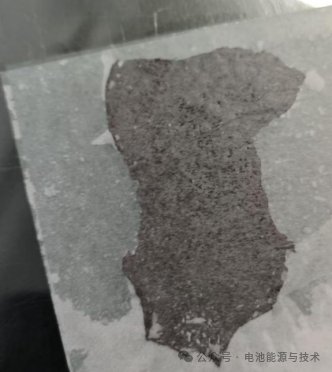

Step 5 – Electrode Film Transfer

The relatively flexible electrode film prepared in the previous step cannot be directly peeled off the glass. It must be transferred onto weighing paper. The specific procedure is as follows: First, add a drop of ethanol onto the film. Then cover it with weighing paper. Use tweezers to lift the edge of the film, peel off the weighing paper, and the film will transfer from the glass plate onto the weighing paper. Subsequently, the electrode can be dried, trimmed to size, and pressed onto the desired current collector.

Source: WeChat Battery Energy and Technology https://mp.weixin.qq.com/s/tXAnHcroamsWqwx4Dig2KQ

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.

Neware was founded in 1998. We are trusted by ATL, BYD, CATL, Tesla, Apple, HUAWEI, SolarEdge, etc. We provide battery testing solutions for testing battery cell, module, pack, supercapacitor, BESS, etc. If you want to do capacity, cycle life, pulse, DCIR, GITT, HPPC, or EV driving simulation test, please feel free to contact us.

If you do battery research or battery materials research, you might be interested in these products: Neware battery testing equipment