Analysis of Appearance Defects in Lithium-ion Battery Coating Processes

Source: WeChat Official Account “Learn Batteries Together” 来源于微信公众号 一起学电池

I. Battery Coating-Related Defects

Battery Coating is the core fundamental process in lithium-ion battery manufacturing, directly determining the uniformity of active material distribution and interfacial stability. It fundamentally dictates the battery’s energy density, cycle life, and safety. Furthermore, quality defects—such as thickness fluctuations, foreign matter, and pinholes—are amplified throughout subsequent processes, leading to a surge in failure risks or even triggering thermal runaway. Consequently, coating quality stands as the primary ‘chokepoint’ for both battery performance and safety.

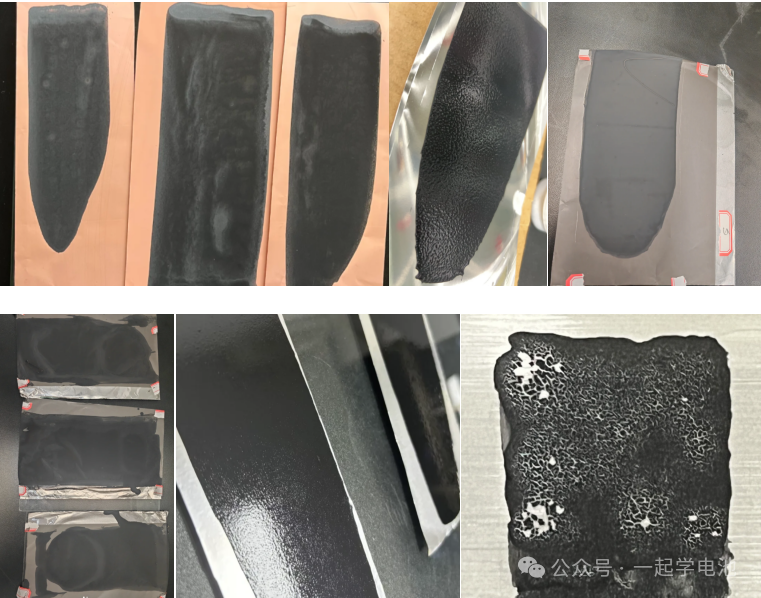

1. Missing Coating / Exposed Foil (See image below)

Description: Parts of the substrate (copper/aluminum foil) are either partially or strip-wise completely uncovered by the slurry, revealing the metallic luster.

Characteristics: Clearly visible metallic strips or spots that provide a sharp contrast against the surrounding coating color.

Potential Root Causes:

Slurry Delivery System Blockage: Clogging in the nozzles or piping.

Coating Head Issues: Blockage or physical damage to the slot die or comma scraper.

Inconsistent Substrate Tension: Uneven tension causing parts of the foil to pull away from the coating head.

Rheological Issues: Poor slurry flowability or sudden fluctuations in viscosity.

Impact: Severely reduces battery capacity and poses a high risk of internal short circuits (due to direct contact between anodes and cathodes), representing a critical safety hazard.

2. Scratches / Streaks (See image below)

Description: Long, slender, line-shaped grooves or raised ridges appearing on the coating surface. These can be “hard scratches” (penetrating down to the substrate) or “soft scratches” (only affecting the surface of the coating layer).

Characteristics: Continuous or intermittent lines running along the Machine Direction (MD) or Cross Direction (CD).

Potential Root Causes:

Coating Tooling Issues: Damage, burrs, or adhered hard particles on the coating head (scraper blade or slot die lip).

Roller Contamination: Damage or foreign matter on the surface of guide rollers or back-up rollers.

Slurry Impurities: Hard, oversized particles or agglomerates mixed within the slurry.

Tension Irregularities: Excessive or unstable winding/unwinding tension, leading to increased friction between the substrate and roller surfaces.

Impact: Disrupts the coating structure and compromises thickness uniformity; this can lead to localized lithium plating, increased internal resistance, and even micro-short circuits.

3. Bubbles / Pinholes (See image below)

Description:

Bubbles: Pockets of gas trapped within the coating or at the interface between the coating and the substrate. After drying, these form circular or elliptical small holes (the surface may be sealed or ruptured).

Pinholes: Tiny holes that penetrate through the entire coating layer to the substrate (usually smaller and deeper than bubble-related voids).

Characteristics: Densely packed or scattered tiny holes visible on the surface or cross-section of the coating. Bubble holes may appear as protrusions or depressions, while pinholes directly expose the substrate.

Potential Root Causes:

Incomplete Slurry Degassing: Air introduced during mixing, transport, or resting periods was not fully removed.

Air Entrainment during Coating: Air trapped at the coating head due to poor design, uneven substrate surface, or excessive coating speeds.

Poor Substrate Wettability: The slurry fails to spread and cover the surface completely due to surface tension issues.

Improper Drying Profile: Solvent evaporates too rapidly during the initial drying stage, causing a “skin” to form on the surface. This traps internal solvent vapors, which then burst through to create bubbles and ruptures.

Impact: Reduces the loading of active materials and increases localized current density. This often leads to lithium plating and short circuits at pinhole sites, significantly shortening cycle life and compromising safety.

4. White Spots / Dark Spots (See image below)

Description: Regions of abnormal color appearing on the coating surface (either whiter or darker than the normal area). These are usually accompanied by localized changes in material composition or density.

Characteristics: Irregularly shaped spots or cloud-like (“mottled”) regions.

Potential Root Causes:

Poor Slurry Dispersion: Agglomeration of conductive agents or binders due to insufficient mixing.

Non-uniform Drying Rates: Uneven hot air distribution or inappropriate wind speeds causing solvent migration and compositional segregation.

Slurry Sedimentation: Solid particles settling out of the suspension if not sufficiently agitated before coating.

Substrate Contamination: Presence of oil stains, fingerprints, or dust on the surface of the foil.

Impact: Disrupts the uniformity of electrical conductivity and bond strength. This creates localized variances in electrochemical performance, which may increase internal resistance and accelerate capacity fade.

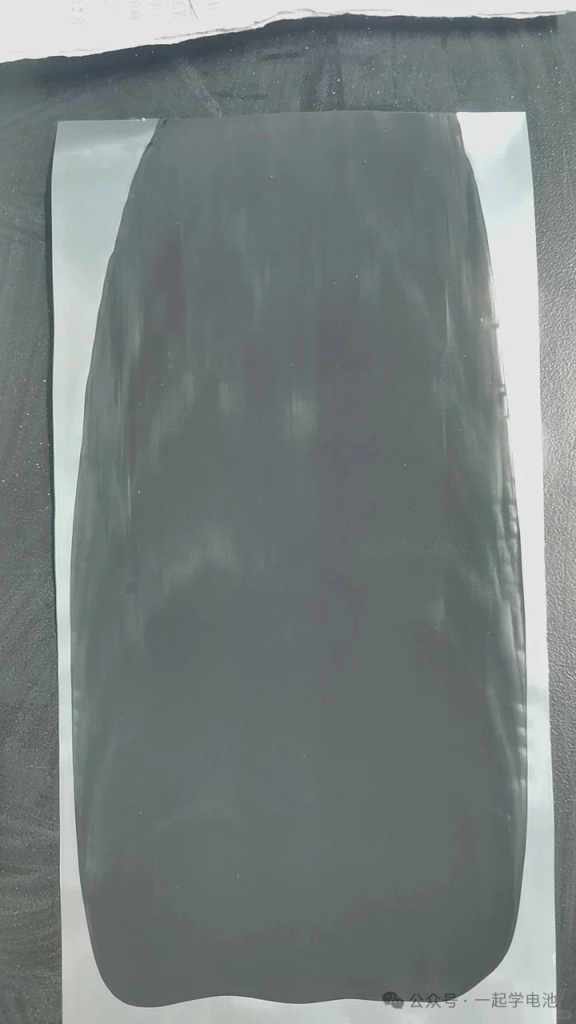

5. Thickness Inconsistency (See image below)

Description: The coating thickness exceeds the allowable process tolerance in either the Cross Direction (CD) or the Machine Direction (MD). This includes overall thickness deviations (too thick/too thin), “heavy edges” (thick edges/thin center or vice-versa), and periodic thickness fluctuations (known as “chatter marks” or “transverse streaks”).

Characteristics: Typically requires detection via thickness gauges (Beta-ray, X-ray, or laser). In severe cases, differences in gloss or color (e.g., whitish edges) are visible to the naked eye.

Potential Root Causes:

Tooling Calibration: Improper setting or adjustment of the coating head (slot die gap or scraper blade pressure).

Slurry Properties: Fluctuations in slurry viscosity or solid content.

Tension Control: Unstable substrate tension during the coating process.

Mechanical Run-out: Radial run-out, vibration, or deformation of the back-up roller or coating roller.

Feed System: Flow rate fluctuations from the slurry supply pump.

Impact: Directly compromises the consistency of battery capacity, internal resistance, and C-rate performance. Excessively thick areas are prone to cracking, while overly thin areas are susceptible to diaphragm piercing or insufficient capacity.

6. Edge Effects (Heavy Edges)

Description: A phenomenon where the coating thickness at both lateral edges is significantly higher than in the central region, forming a profile commonly referred to as “dog-ears.”

Characteristics: Pronounced thickening or build-up of material along the two side edges of the coating track.

Potential Root Causes:

Surface Tension Effects: The formation of a meniscus at the slot die exit leads to increased slurry flow at the boundaries.

Tension Discrepancy: Inconsistency between the substrate tension at the edges versus the center.

Fluid Dynamics: Secondary flows or edge beads occurring as the slurry exits the die or passes the scraper.

Impact: Negatively affects subsequent slitting and winding processes. During winding, the accumulated thickness at the edges causes uneven stress distribution, potentially leading to battery deformation or localized high-pressure points within the cell stack.

7. Foreign Matter / Contamination

Description: Particles, fibers, hair, metal shavings, dust, or other materials not belonging to the slurry composition embedded on the surface or within the coating layer.

Characteristics: Foreign substances of various shapes and sizes.

Potential Root Causes:

Insufficient Cleanroom Standards: Falling dust or particulates in the ambient air.

Personnel-Induced Contamination: Introduction of hair or clothing fibers by operators.

Equipment Wear: Metal shavings generated by mechanical friction or wear and tear of machinery.

Slurry Handling: Foreign matter mixed in during slurry preparation or transport.

Substrate Issues: The current collector (foil) itself carrying pre-existing contaminants.

Impact: One of the most dangerous defects. Metal contaminants, in particular, are highly likely to cause internal short circuits, triggering thermal runaway. Non-metallic foreign matter can also compromise coating uniformity and adhesion.

8. Orange Peel (See image below)

Description: The coating surface exhibits irregular, bumpy ripples resembling the texture of an orange peel.

Characteristics: Micro-scale, non-directional unevenness or “waves” across the surface.

Potential Root Causes:

Poor Leveling Properties: High slurry viscosity or strong thixotropy preventing the slurry from smoothing out.

Improper Drying Profile: Rapid solvent evaporation at the surface during the early drying stage, where surface tension drives ripples because the underlying slurry cannot flow quickly enough to compensate.

Substrate Issues: Uneven surface roughness or non-uniform tension of the foil.

Impact: Primarily affects visual appearance; however, in severe cases, it can slightly compromise coating uniformity and interfacial contact.

II. Substrate-Related Defects

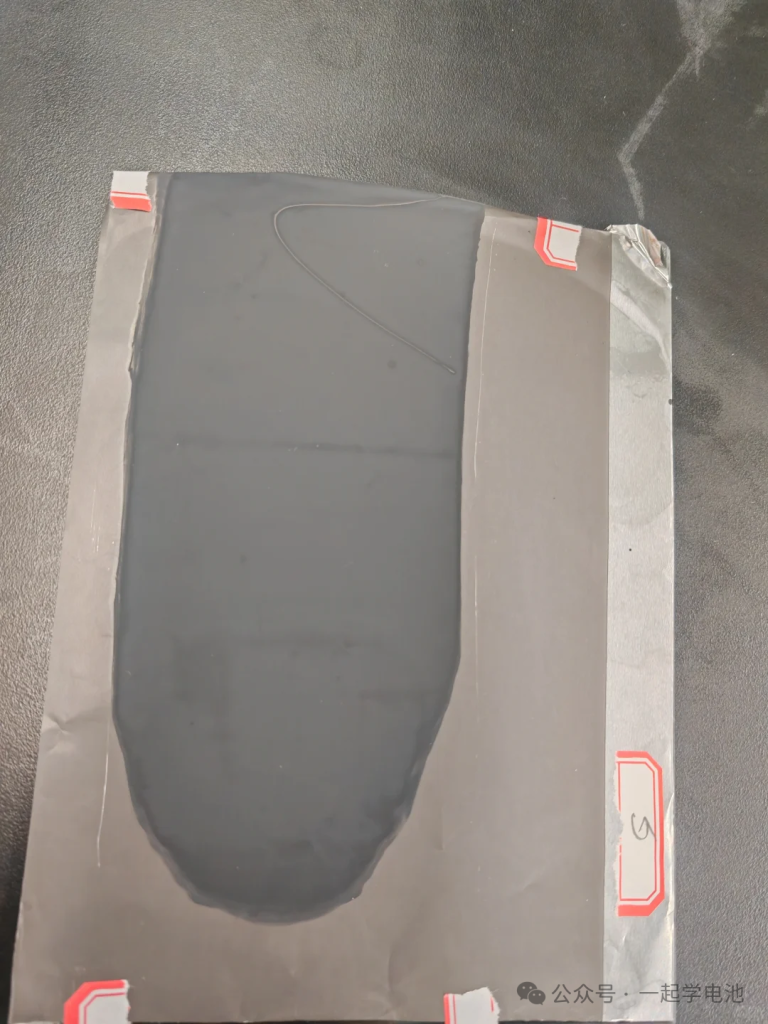

1. Wrinkles (褶皱)

Description: Localized folding, buckling, or arching of the substrate (current collector) during the coating process.

Characteristics: Pronounced wave-like or strip-shaped creases that cause corresponding deformation in the applied coating.

Potential Root Causes:

Tension Control Issues: Improper winding or unwinding tension (excessive, insufficient, or unstable).

Mechanical Misalignment: Non-parallel or deformed guide rollers.

Substrate Quality: Pre-existing internal stress or thickness non-uniformity in the raw foil.

Web Guiding Failure: Malfunctions in the automatic edge position control (EPC) or centering systems.

Impact: Destroys the coating integrity and causes extreme thickness variations. Affected sections cannot proceed to subsequent processes, typically resulting in the scrapping of the entire roll.

2. Tearing / Web Break (撕裂/断带)

Description: The physical snapping or fracturing of the substrate during the coating run.

Characteristics: Complete mechanical failure (breakage) of the metal foil.

Potential Root Causes:

Sudden Tension Spikes: Instantaneous high tension caused by emergency stops or overly aggressive acceleration.

Inherent Material Defects: Pre-existing edge cracks, nicks, or internal structural damage in the foil.

Roller Seizure: Guide rollers getting stuck or failing to rotate smoothly, creating localized drag.

Impact: Results in immediate production downtime, loss of slurry, and significant material waste.

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.