Case Study on Pouch Cell Testing and Analysis

Source: WeChat Official Account “New Energy Era” 新能源时代

Pouch Cell Testing and Analysis Report

1. Test Objects

A comprehensive test was conducted on two pouch cells, covering external dimensions, electrochemical performance, battery design, and material composition. The test parameters were set as follows:

Charge Cut-off Voltage: 4.2 V

Discharge Cut-off Voltage: 2.75 V

Testing Conditions:

Capacity Grading, Low-Temperature, and Safety Tests: Conducted at a 1C current.

Cycle Life Test: Conducted at a 3C current.

2. External Dimensions

Pouch cell 1# This battery is 118mm long, 40mm wide, and 10mm thick, with an internal resistance of 1.7mΩ and a voltage of 3.812V.

3. Capacity performance

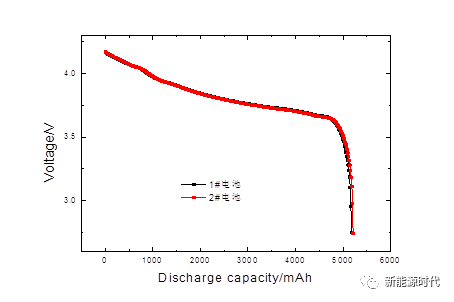

Pouch cell 1# This battery has a 1C discharge capacity of 5178.6 mAh, a charging constant current ratio of 91.41%, and a median discharge voltage of 3.7906V. The #2 battery has a discharge capacity of 5215.0 mAh, a charging constant current ratio of 91.87%, and a median discharge voltage of 3.7868V. The battery weighs 118.39g and has an energy density of 166.80Wh/kg. The battery voltage plateau is relatively high.

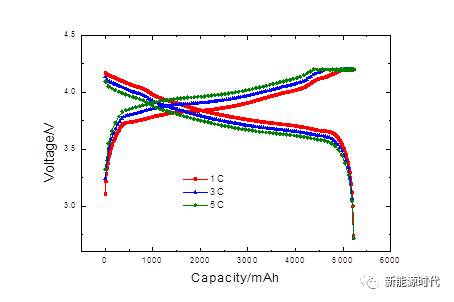

4. Rate performance

Pouch cell 2# This battery has a discharge capacity of 5243.6 mAh at 0.5C, 5220.8 mAh at 1C, 5220.9 mAh at 3C, and 5222.4 mAh at 5C. The constant current ratio is 95.57% at 1C, 88.56% at 3C, and 84.05% at 5C. No bulging occurred after 5C discharge, and the 5C/1C capacity retention rate is 99.60%, indicating good rate discharge performance.

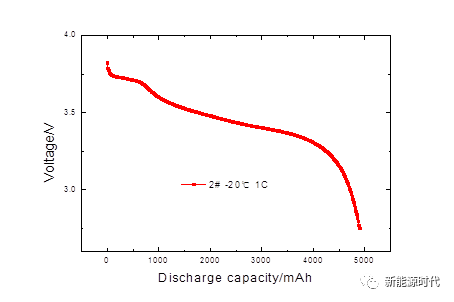

5. Low temperature performance

Pouch cell 2# At -20℃, the 1C discharge capacity is 4904.4mAh, the median discharge voltage is 3.4378V, and the capacity retention rate is 93.66% compared to room temperature, demonstrating excellent low-temperature discharge performance.

—————-> Neware battery testing system

—————-> Neware high and low temp chamber

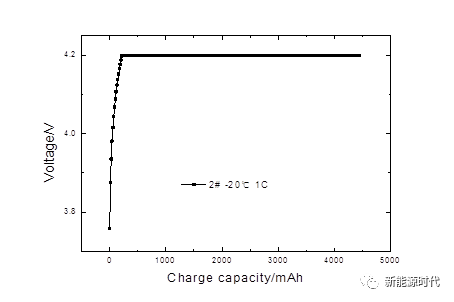

Pouch cell 2# At -20℃, the 1C charging capacity is 4443.6mAh, with a capacity retention rate of 84.99% compared to room temperature, and a charging constant current ratio of 4.87%. The low-temperature charging performance is average.

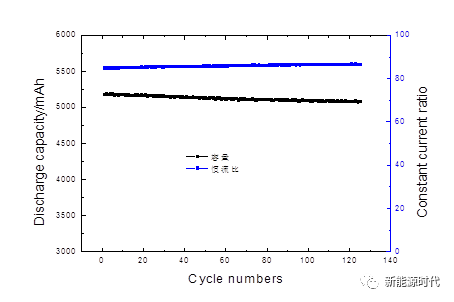

6. Cycle performance

Pouch cell 1# This battery retains 98.14% of its capacity after 125 times 3C cycles and has a constant current charging ratio of 86.65%, demonstrating excellent cycle performance.

7. Safety performance

After cycling, battery #1 was fully charged at 1C and then subjected to a nail penetration test. The results showed that the battery caught fire, emitted thick smoke, and reached a maximum temperature of 396℃.

8. Disassembly and Analysis:

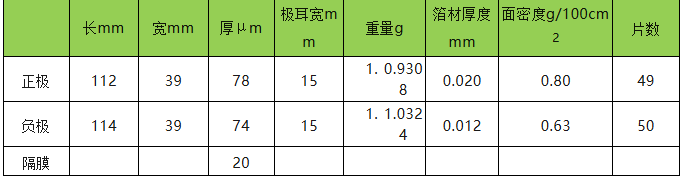

The No. 2 battery was disassembled and analyzed. The electrode size information is shown in the table below.

This battery is composed of 49 positive electrodes and 50 negative electrodes folded together. The positive electrodes are 78 μm thick with an areal density of 0.80, and the negative electrodes are 74 μm thick with an areal density of 0.63. The aluminum foil is 20 μm thick, the copper foil is 12 μm thick, and the separator is 20 μm thick. This battery adopts a low areal density and thickened copper and aluminum foil design, thus exhibiting good rate performance and cycle performance.

9. Material composition analysis

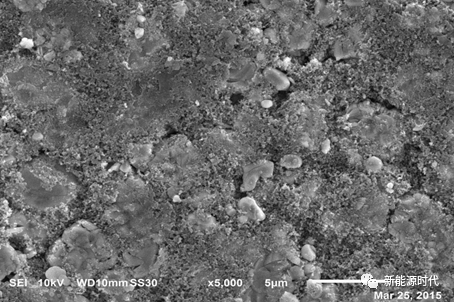

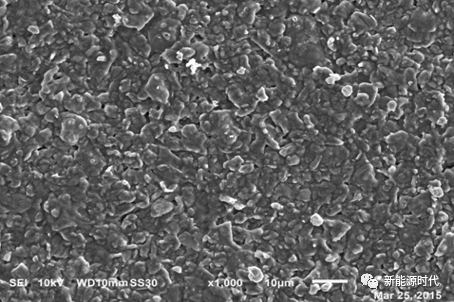

SEM images show that the primary particles of the positive electrode active material are approximately 1 μm in size, agglomerated into spherical shapes, and coated with SP particles. The negative electrode active material is coated with an SEI film and lithium oxide, appearing as a sheet, thus eliminating the mesophase carbon microspheres.

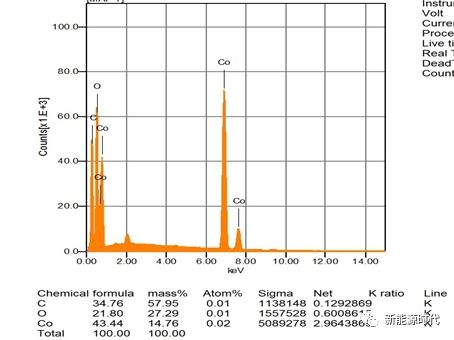

According to EDS results, the positive electrode partial scan showed only C, Co, and O elements, confirming it as LiCoO2 material.

Final conclusion: The two pouch cells exhibit good consistency, a high energy density of 166.80 Wh/kg, excellent low-temperature discharge and rate performance, and good cycle performance. The cells have been identified as lithium cobalt oxide batteries.

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.

Related News:

- Design, Assembly, and Testing of Full Coin Cells: Tutorials and Case Studies 2026 post

- Coin Cells: From Electrode Preparation to Performance Testing (3)

- Electrochemical Test Techniques for Lithium-ion Batteries: CV, EIS

- How do the batteries in Xiaomi phones, Apple phones, and Tesla electric vehicles achieve fast charging?