Battery Aging Introduction

Battery Energy Storage Systems (BESS) and battery packs are integral to various industries, including electric vehicles and renewable energy storage. Ensuring their reliability and longevity requires rigorous aging tests, which simulate real-world conditions to evaluate battery performance degradation over time. This article provides a detailed guide on how to perform aging tests on battery modules, packs, and BESS, focusing on the importance of battery testing equipment and methodologies.

Why Aging Tests are Essential?

Before diving into the “how,” it is vital to understand the “why.” Aging tests simulate years of real-world use in a compressed timeframe to:

- Calculate State of Health (SoH): Determine the remaining useful life of a cell.

- Identify Failure Modes: Spot issues like lithium plating or electrolyte decomposition.

- Validate Warranty Claims: Ensure the battery lasts the promised 5–10 years.

Understanding Aging Tests

Aging tests are designed to simulate the long-term effects of repeated charge-discharge cycles and environmental conditions on batteries. These tests help predict battery lifespan and reliability under different operational scenarios. The primary goal is to identify potential failure points and optimize battery performance.

Key Factors in Aging Tests

1. **Temperature**: Temperature significantly impacts battery aging. Higher temperatures accelerate the aging process, while lower temperatures slow it down.

2. **Charge-Discharge Cycles**: Repeated cycling at different rates (C-rates) affects battery capacity and internal resistance.

3. **Depth of Discharge (DOD)**: The extent to which a battery is discharged affects its aging. Higher DOD generally leads to faster degradation.

Equipment for Aging Tests

To perform effective aging tests, specialized equipment is required. These include:

1. **Temperature-controlled Chambers**: These cabinets provide controlled temperature and humidity conditions to simulate real-world environments. These chambers simulate high and low temperatures to test the performance of batteries in different temperatures.

2. **High Precision Battery Testers**: Battery testing equipment like the NEWARE 60V100A, 100V200A, 60V300A, and 1500V300A precision battery testers are used for accurate charge-discharge cycle testing.

Methodology for Aging Tests

1. **Preparation**: Ensure the battery packs are fully charged and conditioned.

2. **Test Plan**: Develop a detailed test plan that includes the number of cycles, temperature ranges, and DOD levels.

3. **Equipment Setup**: Set up the battery aging equipment or temperature chamber according to the test plan.

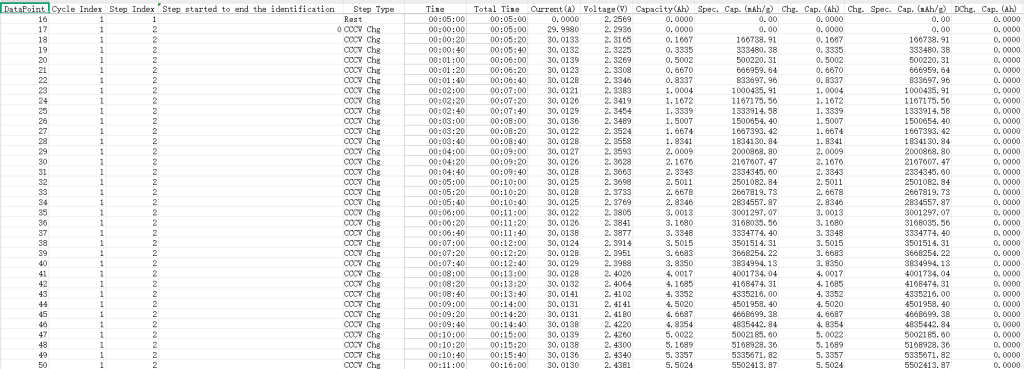

4. **Execution**: Start the test and continuously monitor battery performance. Record data on voltage, current, capacity, and temperature.

5. **Data Analysis**: Analyze the data to assess degradation in battery capacity and internal resistance.

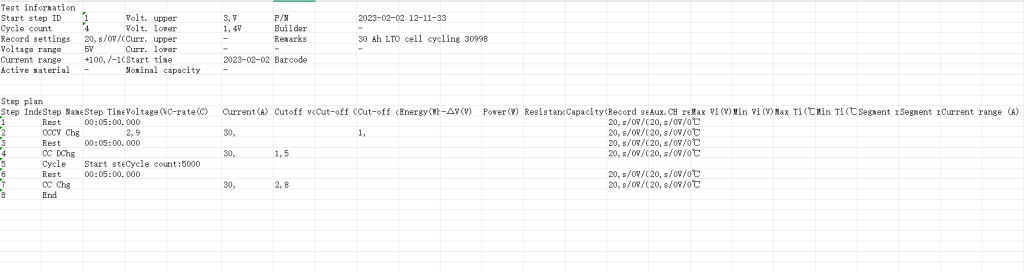

Test data

Step-by-Step Practical Procedure for Cycle Aging

To perform a professional-grade aging test, follow these specific operational steps:

Step 1: Initial Characterization (The Baseline)

Before starting the aging process, you must establish a “Born Clean” baseline.

- Visual Inspection: Check for leaks or swelling.

- Capacity Check: Perform 3 full charge/discharge cycles at a 0.5C rate.

- Internal Resistance (DCIR/ACIR): Measure the resistance using a 1kHz AC signal or a DC pulse test.

Step 2: Setting the Test Parameters

Define your “Stress Factors” based on the intended use case:

- Temperature: Usually set in a thermal chamber at 45°C to accelerate aging (chemical reactions double roughly every 10°C increase).

- Voltage Limits: Set the upper and lower cutoff (e.g., 4.2V to 3.0V for Li-ion).

- C-Rate: Use 1C for standard testing or 2C+ for “Fast Charge” stress testing.

Step 3: Executing the Aging Loops

The battery is placed in a battery cycler (e.g., Arbin, Neware, or Maccor) and put through repeated loops:

- Constant Current (CC) Charge: Charge at the defined C-rate until the voltage limit is hit.

- Constant Voltage (CV) Charge: Hold voltage until current drops to a “cutoff” (usually 0.05C).

- Rest Period: Allow 10–30 minutes for thermal stabilization.

- Discharge: Discharge to the lower limit.

Step 4: Periodic Reference Performance Tests (RPT)

Every 50 or 100 cycles, pause the stress test to perform an RPT at room temperature (25°C). This involves:

- Measuring actual remaining capacity.

- Updating the SoH percentage.

- Analyzing the Voltage vs. Capacity curve shift.

Analyzing the Results: When is a Battery “Dead”?

In most industry standards (like ISO 12405 or IEC 62660), a battery is considered to have reached its End of Life (EoL) when:

- Capacity Fade: The capacity drops below 80% of its original rating.

- Resistance Growth: The internal resistance doubles (200% of baseline).

Importance of Battery Testing Equipment

Battery testing equipment is essential for accurate and reliable aging tests. Equipment like the Battery Aging Cabinet and Temperature Cycling Chamber provide the necessary conditions to simulate real-world usage scenarios. These devices help in evaluating the performance degradation of batteries under different operational conditions, ensuring their reliability and longevity.

Case Study: Evaluation of Lithium Battery Cycle Aging Based on Temperature

A recent study evaluated the cycle aging of lithium-ion batteries based on temperature, highlighting the importance of temperature control in aging tests. The study used a high-energy-density ternary pouch lithium-ion battery and subjected it to charge-discharge cycles at a fixed rate to induce accelerated aging. The results showed that temperature increase behavior correlated with lithium plating characteristics and overall battery degradation. This study underscores the importance of monitoring temperature changes during the aging process to provide a comprehensive aging diagnostic framework.

Conclusion

Aging tests are crucial for evaluating the performance and lifespan of battery modules, packs, and BESS. By using specialized equipment and following a structured methodology, manufacturers and researchers can simulate real-world conditions and identify potential failure points. This comprehensive approach ensures that batteries are reliable and perform optimally over their intended lifespan. Future research will focus on integrating real-world operational data, validating across different battery chemistries and configurations, and conducting tests under varying ambient conditions to enhance the applicability of aging assessment methods.

About Neware

Neware was founded in 1998. We are trusted by ATL, BYD, CATL, Tesla, Apple, HUAWEI, SolarEdge, etc. We provide battery testing solutions for testing battery cell, module, pack, supercapacitor, BESS, etc. If you want to do capacity, cycle life, pulse, DCIR, GITT, HPPC, or EV driving simulation test, please feel free to contact us.