How to make a pouch cell in lab without equipment?

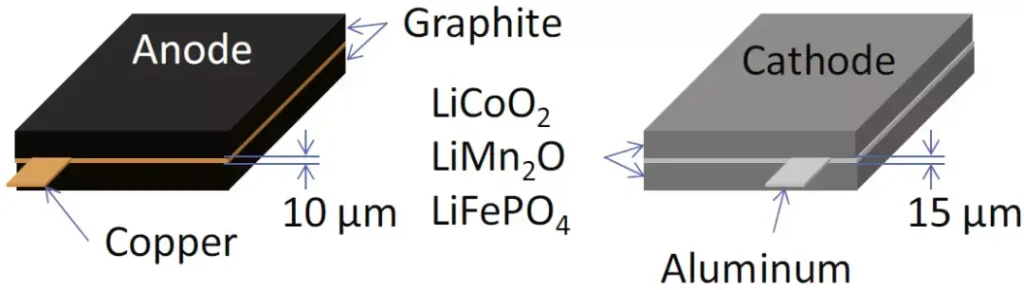

As we know, the normal process for making pouch cells involves preparing the electrode sheets, then cutting the positive and negative electrodes using a film-cutting machine, cutting the aluminum-plastic film using an aluminum-plastic film forming machine, and welding the tabs using an ultrasonic spot welder. In the laboratory, lithium negative electrodes are generally used (it’s even more convenient if zinc electrodes, which can be assembled in air, are used). The next step is to transfer the batteries to a glove box and stack them using manual stacking fixtures or an automatic stacking machine. Finally, they are sealed using a top-side sealing, electrolyte injection, and final sealing machine to obtain the pouch cell.

In the absence of such equipment, we need to find methods to replace the equipment used in the process.

1. Cutting

We can cut the positive electrode of the membrane by hand. You can buy a utility knife to cut it, which allows you to control the size of the cut. Generally, the size of a small pouch electrode is 4.2 x 5.6 cm. You can cut an electrode of a similar size with a utility knife. Of course, you also need to cut a blank aluminum foil to calculate the weight of the active material (the separator and lithium sheet are also cut in this way. Note that the separator has the largest area, and the lithium sheet has the second largest area).

2. Tabs

Ultrasonic spot welding machines can weld tabs by bonding the tabs to the electrode sheet with conductive adhesive, or by using conductive adhesive directly as the tab (placing the tab on the back of the positive electrode or lithium sheet and bonding it with conductive adhesive). I recommend bonding the tabs to the electrode sheet with conductive adhesive because if you use conductive adhesive directly as the tab, the sealing performance may not be good.

3. Sealing

The top and side sealing and final sealing machines can be replaced by a hand-operated sealing machine (around 30 RMB). Note that the sealing machine temperature should be set to the highest setting, and the sealing time should be longer. If leakage still occurs, try sealing multiple times. Additionally, after filling the pouch, press down on it to expel any air inside. You can also place it in the transition chamber and slowly create a vacuum to further expel air from the pouch.

4. Electrolyte Injection

The electrolyte is added directly using a pipette. For beginners, it’s recommended to add a little more electrolyte, as there will likely be many empty spaces initially. Adding more electrolyte ensures the electrolyte thoroughly wets the electrode. Test your pouch——>Neware battery cyclers

Neware was founded in 1998. We are trusted by ATL, BYD, CATL, Tesla, Apple, HUAWEI, SolarEdge, etc. We provide battery testing solutions for testing battery cell, module, pack, supercapacitor, BESS, etc. If you want to do capacity, cycle life, pulse, DCIR, GITT, HPPC, or EV driving simulation test, please feel free to contact us.

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.

A Guide to Making Highly Reproducible Li-Ion Single-Layer Pouch Cells for Academic Researchers

Test you pouch cells—>Neware battery cyclers

Related News:

- Detailed Explanation of BYD 4680 Cylindrical Battery Cell Design and Performance

- Coin Cells: From Electrode Preparation to Performance Testing (1)

- A Guide to Making Highly Reproducible Li-Ion Single-Layer Pouch Cells for Academic Researchers Published August 23, 2023.

- Lithium Battery Binders: Types and Mechanisms 2024