Neware End-of-line (EOL) equipment 2026 update

EOL (End-of-Line) testing is the final testing stage in the battery production process.

Objective: To ensure that every battery pack meets functionality, safety, and performance requirements before leaving the factory.

Testing Goals:

Ensure Product Safety and Reliability: Guarantee that products are safe and reliable upon shipment.

Early Detection of Manufacturing Defects: Identify defects early to reduce the risk of recalls.

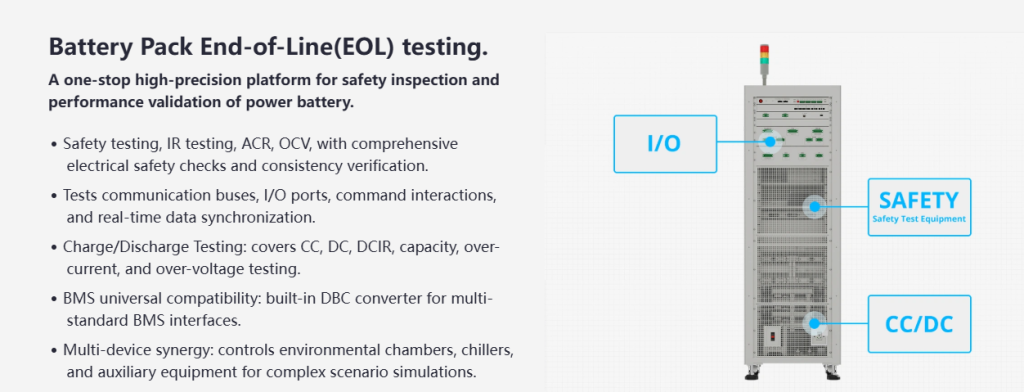

1. EOL Test Equipment List and Functions

| Equipment Name | Model | Functional Description |

| Safety Compliance Tester | Chroma 19073 | Insulation Resistance, Dielectric Withstand (Hipot) Testing |

| Digital Multimeter | Agilent 34461A | Precision Voltage / Current / Resistance Measurement |

| Battery Internal Resistance Tester | HIOKI BT-3563 | Cell Voltage, Internal Resistance Measurement (ACIR) |

| Programmable DC Power Supply | MPS-3610 | Output stable voltage/current, simulate operating states |

| Charge/Discharge Module | 200V / 200A | Charge/discharge testing, functional verification, and parameter metrics |

The battery charge/discharge module portion can be customized. Other components can also be selected from alternative brands.

2. Introduction to EOL Test Items

Dielectric Withstand Test (HIPOT)

HIPOT (High Potential) Test: A destructive test designed to apply a high voltage—significantly higher than the standard operating voltage—to the Device Under Test (DUT). The purpose is to verify whether the insulation structure can withstand such overvoltage and to detect potential insulation defects, such as insufficient clearances or the presence of impurities. This is one of the most critical tests for electrical safety.

Insulation Resistance Test (IR)

Insulation Resistance (IR) Test: A non-destructive test aimed at measuring the resistance value of insulating materials under a DC voltage. Its purpose is to evaluate whether the quality of the insulation material is sound and to detect if it is affected by moisture, aging, or contamination.

AC Internal Resistance (ACIR) and Open Circuit Voltage (OCV) Measurement

Testing Principle: The instrument generates a constant AC test current (typically very low) and applies it across the battery terminals. By detecting the AC voltage drop across the battery and applying Ohm’s Law (Z = V / I), the instrument calculates the battery’s AC internal resistance (ACIR).

| Function | Measurement Object | Objective |

| DC Voltage Measurement | Total Voltage, Series Voltage, BMS Supply Voltage | Verify basic output, cell balancing, and BMS operating conditions |

| Continuity Test | Fuses, Connectors, Wiring Harnesses | Troubleshoot open circuits and verify assembly integrity |

| Resistance Measurement | Connection points, Circuits | Rough assessment of connection reliability |

| Current Measurement | Standby Current | Verify BMS sleep mode power consumption |

By utilizing communication functions, the test system transitions from passive measurement to active interaction, enabling the verification of whether the BMS is functioning correctly.

If you want to know more information about Neware EOL testing equipment, please feel free to contact Neware!

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.