How to make lithium-ion battery cathode electrodes? Typical formulation example (using NCM811 as an example)

Core Objective: To uniformly mix the active material, conductive agent, and binder and firmly coat the mixture onto the current collector (typically aluminum foil), forming a stable thin layer with excellent electronic/ionic pathways.

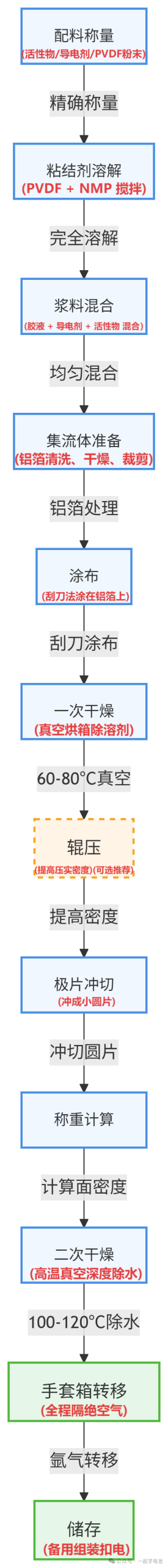

Electrode Preparation Flowchart Translation

Material Weighing (Active material / Conductive agent / PVDF powder)

Accurate Weighing

Binder Dissolution (PVDF + NMP stirring)

Complete Dissolution

Slurry Mixing (Conductive agent + Active material mixed)

Uniform Mixing

Current Collector Preparation (Aluminum foil cleaning, drying, cutting)

Aluminum Foil Treatment

Coating (Doctor blade method on aluminum foil)

Doctor Blade Coating

Primary Drying (Vacuum oven to remove solvent)

60-80°C Vacuum

Rolling (Compaction) (Ensure thickness is uniform and controllable)

Increase Density

Electrode Punching (Punching into small discs)

Punched Discs

Weighing and Calculation

Calculate Areal Density

Secondary Drying (High-temperature vacuum deep dehydration)

100-120°C Water Removal

Glovebox Transfer (Isolated from air throughout)

Argon Gas Transfer

Storage (Ready for coin cell assembly)

Typical Formulation Example (Taking NCM811 as an example):

Active Material (NCM811): 90 wt%

Conductive Agent (Super P): 5 wt%

Binder (PVDF): 5 wt%

Solvent (NMP): Appropriate amount (typically with a solid content of around 40-60%, adjusted based on viscosity)

Main Process for Preparing Lithium Battery Cathode Electrodes Typical formulation example (using NCM811 as an example):

1. Material Weighing

Objective: To accurately weigh each component.

Specific Steps:

Calculate the total amount of slurry required based on the needed number of electrode sheets and their surface area.

Use a precision electronic balance (with an accuracy of at least 0.1 mg) to weigh the active material powder, conductive agent powder, and binder powder separately.

This weighing process must be conducted in a dry environment, such as a glovebox or a dry room.

Practical Example: Suppose you need to coat 5 electrode sheets with a diameter of 12 mm (effective single-sided coating area is approximately 1.13 square centimeters). If the target areal density is about 10 mg per square centimeter, the active material for a single side is approximately 11.3 mg. Accounting for double-sided coating and material loss, the total active material requirement for 15 sheets is: 15 sheets * 11.3 mg/sheet ≈ 170 mg. Based on a formula where the active material is 90%, the total dry material is: 170 mg / 0.9 ≈ 189 mg.

NCM811: ≈ 170 mg

Super P: ≈ 9.45 mg (189 mg * 0.05)

PVDF: ≈ 9.45 mg (189 mg * 0.05)

Key Requirement: You must record the exact mass of every component!

Important Considerations:

Moisture Protection: Active materials and conductive agents absorb moisture easily; weighing should be done quickly or inside a glovebox.

Precision: When dealing with small samples, even tiny weighing errors can have a massive impact on battery performance.

Cleanliness: Ensure weighing paper, dishes, and tools are kept dry and clean to prevent cross-contamination.

2. Binder Dissolution

Objective: To fully dissolve the PVDF binder in the NMP solvent to form a uniform adhesive solution.

Specific Steps:

Pour the calculated volume of NMP solvent into a suitable container, such as a small glass vial or sample tube. The typical weight ratio is PVDF to NMP at approximately 1:9 to 1:12.

Slowly add the weighed PVDF powder into the NMP in batches, stirring with a glass rod or small spatula while adding to prevent clumping.

Seal the container tightly to prevent NMP evaporation and moisture absorption.

Place the container on a magnetic stirrer and insert a clean magnetic stir bar.

Stir at a low speed (to avoid creating excessive air bubbles) for several hours or even overnight until the PVDF is completely dissolved.

Result: The final product should be a transparent or translucent, uniform, and viscous adhesive solution.

Key Requirement: Ensure complete dissolution with absolutely no visible particles!

Practical Example:

Weigh 9.45 mg of PVDF and add approximately 100 mg of NMP (based on a 1:10.5 ratio).

Set the stirring speed to 300–500 rpm and stir for 4–6 hours or overnight.

Important Considerations:

NMP Toxicity: NMP is toxic; perform the entire operation inside a fume hood and wear nitrile gloves.

Slow Addition: Adding PVDF too quickly leads to clumping, which makes it extremely difficult to dissolve later.

Sealing: NMP is volatile and hygroscopic (absorbs water easily), so the container must be capped tightly.

3. Slurry Mixing and Stirring

Objective: To uniformly disperse the active material and conductive agent into the PVDF adhesive solution, forming a stable, homogeneous slurry with appropriate viscosity.

Specific Steps:

Transfer the Solution: Move the fully dissolved PVDF adhesive solution into a larger mixing container, such as a small sample tube or a mortar.

Add Conductive Agent (Super P) First: Add the weighed conductive agent powder into the adhesive solution.

Manual Pre-mixing: Use a spatula or glass rod to perform a preliminary manual pre-mix, ensuring the dry powder is roughly wetted by the adhesive to form a paste-like consistency. This step is crucial to prevent the conductive agent from flying away or forming subsequent clusters.

First Addition of Active Material: Add approximately half of the weighed active material powder.

Initial Mixing: Continue manual stirring or use a small planetary centrifugal mixer (such as a Thinky ARE-310) at low speeds (e.g., 1000–1500 rpm for 1–2 minutes) to achieve preliminary uniformity.

Final Addition: Add the remaining active material powder.

Formal Stirring (Two Methods):

Highly Recommended: Planetary Centrifugal Mixer (Thinky):

Place the mixture into a dedicated Thinky cup.

Set the program (e.g., 2000 rpm stirring for 2 minutes → 2200 rpm degassing for 1.5 minutes → repeat 2–3 times).

Centrifugal stirring achieves powerful mixing and high-efficiency degassing simultaneously, yielding far better results than manual methods.

Manual Method:

Use a spatula in a mortar to repeatedly grind and scrape in one direction with uniform force for an extended period (10–15+ minutes) until no obvious particles remain and the color is uniform.

This requires significant patience and skill; otherwise, the slurry may remain non-uniform.

Check Slurry Status: An ideal slurry should look like thick chocolate sauce: smooth, fine, and free of visible particles or clusters. When lifted with a spatula, it should flow down slowly and continuously without breaking.

Practical Example (Using Thinky Mixer): In a Thinky cup, follow this sequence: Add PVDF adhesive solution → Super P → Manual pre-mix → Add half of the NCM811 → Thinky low-speed mix (1500 rpm, 1 min) → Add remaining NCM811 → Thinky program (2000 rpm for 2 min, 2200 rpm for 1.5 min, 2 cycles).

Important Considerations for Slurry Preparation

Mixing Sequence: Generally, adding the conductive agent first is beneficial for achieving better dispersion. Adding the active material in batches helps ensure a more uniform mixture.

Viscosity Control: If the slurry is too thin (low solid content), it will flow too easily during coating; if it is too thick (high solid content), the coating process becomes difficult and the surface will likely be uneven. This can be adjusted by fine-tuning the amount of NMP.

Bubble Removal (Degassing): Air bubbles in the slurry will form pinholes after coating and drying, which negatively impacts battery performance. The Thinky mixer’s degassing function is highly effective for this. If mixing manually, the slurry must be allowed to sit for a period to let bubbles dissipate.

Uniformity: This is one of the most critical steps, as it directly affects the reproducibility of battery performance.

4. Current Collector Preparation

Objective: To prepare clean and flat aluminum foil to serve as the current collector.

Specific Steps:

Select Material: Take a piece of clean aluminum foil (typically 12–20 μm thick).

Ethanol Cleaning: Use a lint-free cloth or degreased cotton ball soaked in anhydrous ethanol to gently wipe the surface of the aluminum foil in a single direction 1–2 times. This removes surface oils and oxides. Key: Apply very light pressure to avoid creating wrinkles or scratches!

Deionized Water Rinse: Wipe the surface in the same manner with deionized water to remove residual ethanol and impurities.

Drying: Hang the foil or lay it flat on a clean surface (such as a Petri dish) and place it in a vacuum oven. Dry at 80–120°C for at least 2 hours (or overnight) to thoroughly remove moisture. Allow it to cool to room temperature before use.

Cutting: Cut the dried aluminum foil into appropriate sizes for subsequent coating operations (e.g., strips 2–3 cm wide).

Practical Example:

Cut aluminum foil into strips 2 cm wide and 10 cm long.

Ethanol wipe → Water wipe → Vacuum bake at 120°C for 3 hours.

Important Considerations:

Avoid Scratches: Aluminum foil is very soft and thin; handle it with extreme care. The edges are very sharp (be careful not to cut your hands!).

Thorough Drying: Residual moisture will severely affect adhesion and battery performance.

Cleanliness: Ensure that the lint-free cloths and the work surface are kept clean.

5. Coating

Objective: To apply the slurry onto the aluminum foil uniformly and smoothly with a controllable thickness.

Specific Steps (Doctor Blade Method – Most Common in Labs):

Fix the Foil: Secure the dried aluminum foil strip flat and wrinkle-free onto a glass plate or a flat stainless steel plate (small amounts of tape can be used to fix both ends).

Apply Slurry: Take an appropriate amount of slurry (a pea-sized drop is enough for a small electrode) and place it at one end of the aluminum foil.

Position the Blade: Hold the doctor blade perpendicular to the foil surface, maintaining a fixed angle (usually 15–45 degrees).

Execute Coating: Use a stable, uniform speed and force to scrape the slurry toward the other end in a single motion. The gap between the blade and the foil determines the wet film thickness. Key: Maintain uniform speed and constant force; complete the stroke in one go and avoid back-and-forth scraping!

Inspection: Remove the blade and check the coating. Ideally, the surface should be flat, smooth, free of streaks, with no “pinholes” (exposed aluminum foil), and no material buildup.

Thickness Control: The blade gap can be controlled using spacers (such as tape of a known thickness) or a built-in height adjustment knob on the applicator. The ultimate goal is to control the dry areal density (mg/cm²) by managing the wet film thickness.

Practical Example:

Stick two parallel strips of 150 μm thick tape onto a glass plate as spacers, with a 1.5 cm gap between them. Place and fix the aluminum foil strip in the middle. Drop the slurry and use a flat blade (if no adjustment knob is available) resting on the two tape strips to scrape through at a steady speed. The target wet film thickness is 150 μm.

Important Considerations:

Technique: This is the skill that requires the most practice in the lab! Consistency is key. Moving too fast causes “exposed white” spots, while moving too slow leads to accumulation; uneven force results in uneven thickness.

Environment: It is best to operate in a low-humidity environment (dry room or glovebox transition chamber) to prevent the slurry from absorbing moisture.

Thickness/Areal Density: These are critical parameters! The wet film thickness must be precisely calculated based on the slurry’s solid content and the required dry film areal density, then repeatedly verified. The final result is determined by the actual areal density calculated after drying and weighing (mg/cm²).

Tool Cleaning: Clean the blade and glass plate with NMP immediately after use.

6. Drying

Objective: To completely remove the solvent (NMP) from the slurry, allowing the coating to solidify and take shape.

Specific Steps:

Immediate Transfer: Move the coated wet electrode (along with the supporting glass plate) into a vacuum oven immediately. Key: Dry as soon as possible to prevent the slurry from flowing (deformation) or absorbing moisture.

Set Oven Temperature: Set the temperature to 60–80°C (specifically for PVDF binders). Excessively high temperatures may lead to binder failure or changes in the active material’s structure.

Apply Vacuum: Evacuate the oven to a vacuum level below -0.1 MPa.

Drying Duration: Typically at least 6–8 hours, or even overnight, to ensure NMP has completely evaporated.

Cooling: Once drying is complete, allow the electrode to cool to room temperature under vacuum or an inert atmosphere (such as Argon) before removal. This prevents the hot electrode from absorbing moisture upon contact with air.

Practical Example:

Dry in a vacuum oven at 80°C for 8 hours.

After turning off the heat, continue the vacuum and allow it to cool to room temperature (takes approximately 2 hours).

Important Considerations:

Temperature Control: Strictly control the upper temperature limit (PVDF should generally not exceed 80°C during this stage).

Vacuum: Using a vacuum accelerates solvent evaporation and prevents material oxidation.

Slow Cooling: Sudden cooling (quenching) may cause the coating to crack or curl.

Moisture Avoidance: Isolating the material from air during the cooling process is critical.

7. Calendering (Optional, but Strongly Recommended)

Objective: To increase coating density and compactness, enhance contact between the active material, conductive agent, and current collector, and reduce interfacial resistance.

Specific Steps:

Removal: Carefully remove the dried and cooled electrode from the glass plate, ensuring the coating does not peel off.

Equipment: Use a small laboratory roll press (either manual or electric).

Parameter Setting: Calculate the required thickness reduction based on the target compaction density (g/cm³), or set the roller gap directly.

Execution: Slowly and steadily feed the electrode (with the coating facing the same side) through the rotating rollers once. Key: Maintain a uniform feeding speed; avoid pauses, which can cause uneven thickness or fractures.

Inspection: The pressed electrode should appear smoother, denser, and have a metallic luster, with no visible cracks or powder shedding.

Practical Example:

Target: For NCM811, the target compaction density is approximately 3.3 g/cm³.

Calculation: Measure the coating thickness after drying and calculate the compression ratio (e.g., pressing from 70 μm down to 50 μm).

Operation: Set the roller gap to 50 μm (including the aluminum foil thickness) and press through once at a steady speed.

Important Considerations:

Pressure/Gap: Set these parameters carefully based on material characteristics; excessive pressure can cause particle crushing, coating delamination, or foil breakage.

Frequency: Usually, a single pass is sufficient; avoid repeated rolling.

Alignment: Ensure the electrode is fed in flat to prevent wrinkling.

Powder Shedding: Minor shedding is often unavoidable, but severe shedding indicates issues with slurry dispersion or bonding.

8. Electrode Punching and Weighing

Objective: To obtain circular electrode discs with precise dimensions and known mass for coin cell assembly.

Specific Steps:

Preparation: Place the calendered (or dried) large electrode sheet on a hard, flat backing plate, such as a PVC or Teflon board.

Punching: Use a precision disc cutter (e.g., 12 mm or 14 mm diameter) and align it with a region of the electrode that has a highly uniform coating.

Execution: Apply uniform, vertical downward pressure to punch out the circular electrode.

Handling: Carefully remove the circular electrode using precision tweezers, avoiding any bending or crushing of the coating.

Weighing: Use a high-precision electronic balance (accuracy of 0.01 mg) to weigh the mass of each circular electrode (m_total).

Baseline Measurement: Use the same cutter to punch out blank aluminum foil discs of the same size and weigh them to find the average mass of the current collector (m_Al).

Calculation of Areal Density: * Active Material Areal Density = (m_total – m_Al) / Electrode Area * (Mass percentage of active material in dry matter).

Practical Example:

Punch a circular electrode using a 12 mm die.

Measured mass (m_total) = 15.62 mg.

Average mass of 12 mm blank aluminum foil (m_Al) = 4.50 mg.

Coating mass = 15.62 – 4.50 = 11.12 mg.

Effective Area = π * (0.6 cm)² ≈ 1.13 cm².

Total coating areal density = 11.12 mg / 1.13 cm² ≈ 9.84 mg/cm².

NCM811 active material areal density = 9.84 mg/cm² * 90% ≈ 8.86 mg/cm².

Important Considerations:

Cutter Sharpness: A dull die can cause burrs or electrode deformation; maintain tools regularly.

Vertical Pressure: Punching at an angle will lead to distorted shapes or inaccurate dimensions.

Contamination Prevention: Keep tweezers and the work surface clean.

Precision Weighing: Accuracy here is fundamental to calculating the active material mass correctly.

Documentation: Record the areal density of every single disc for subsequent analysis.

9. Secondary Vacuum Drying and Storage

Objective: To completely remove any trace amounts of moisture that may have been absorbed during the punching process, ensuring the electrodes are absolutely dry before battery assembly.

Specific Steps:

Container Loading: Place all punched circular cathode discs into a glass weighing bottle or sample tube.

Vacuum Baking: Place the open container into a vacuum oven.

Temperature Setting: Set the temperature to 100–120°C. Since the coating is already solidified at this stage, a slightly higher temperature is beneficial for deep dehydration.

Vacuum Level: Apply a high vacuum (down to -0.1 MPa).

Drying Duration: Dry for 8–12 hours.

Cooling: After drying, allow the electrodes to cool to room temperature inside the vacuum oven while maintaining the vacuum.

Glovebox Transfer: Seal the container containing the cooled electrodes tightly (e.g., using a lid with a sealing ring and Parafilm). Quickly transfer the container into a glovebox filled with inert gas, such as Argon. Key: The electrodes must not come into contact with air during this entire process!

Storage: Inside the glovebox, store the electrodes in a sealed container or a dedicated drying cabinet until they are ready for use.

Practical Example:

Dry in a vacuum oven at 120°C for 12 hours.

Turn off the heat and maintain the vacuum until it reaches room temperature.

Transfer into the glovebox main chamber via the ante-chamber after the required purge/vacuum cycles.

Store in a dry storage box inside the glovebox.

Important Considerations:

Moisture/Air Isolation: This is the most critical factor for the success of lithium metal batteries! Any trace of moisture will react violently with lithium metal, consuming active lithium, generating gas, and degrading performance.

Temperature: The temperature for secondary drying can be slightly higher than that of the primary drying stage.

Container Sealing: The container must be absolutely airtight during the transfer process.

Glovebox Environment: Ensure the moisture and oxygen levels in the glovebox are sufficiently low (typically H2O < 0.1 ppm, O2 < 0.1 ppm).

Here is the comprehensive checklist for the lithium battery cathode preparation process, summarized from the previous steps:

Cathode Electrode Preparation Checklist

1. Material Weighing

[ ] Calculate total slurry volume and component masses based on target areal density.

[ ] Weigh NCM811, Super P, and PVDF in a dry environment using a 0.1 mg precision balance.

[ ] Safety: Use a glovebox for moisture-sensitive powders.

2. Binder Dissolution

[ ] Mix PVDF and NMP (typical ratio 1:9 to 1:12).

[ ] Stir at 300–500 rpm until the solution is clear and transparent.

3. Slurry Mixing

[ ] Add conductive agent (Super P) to the glue and manual pre-mix to form a paste.

[ ] Add active material (NCM811) in batches.

[ ] Mixing: Use a planetary centrifugal mixer (e.g., Thinky) for final homogenization and degassing.

[ ] Check: Ensure the slurry flows continuously like “chocolate sauce”.

4. Current Collector Preparation

[ ] Clean aluminum foil (12–20 μm) with ethanol followed by deionized water.

[ ] Bake in a vacuum oven at 80–120°C for at least 2 hours.

5. Coating & Primary Drying

[ ] Apply slurry using the doctor blade method at a constant speed and force.

[ ] Primary Drying: Bake at 60–80°C under vacuum for 6–8 hours immediately after coating.

6. Calendering (Compaction)

[ ] Pass the dried electrode through a roll press to reach the target density (e.g., 3.3 g/cm³).

[ ] Ensure the surface is smooth with a metallic luster.

7. Punching & Weighing

[ ] Punch discs using a 12 mm or 14 mm die.

[ ] Weigh each disc (0.01 mg precision) and calculate the specific active material mass.

8. Secondary Drying & Storage

[ ] Final Bake: Dehydrate at 100–120°C under high vacuum for 8–12 hours.

[ ] Transfer: Move to an Ar-filled glovebox without air exposure.

[ ] Storage: Keep in a sealed container inside the glovebox.

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.