- Q1: About CAN and RS485, which are the basic improvements and functionalities that battery module or pack communication incorporates into NEWARE software? Can this data be saved in the database?

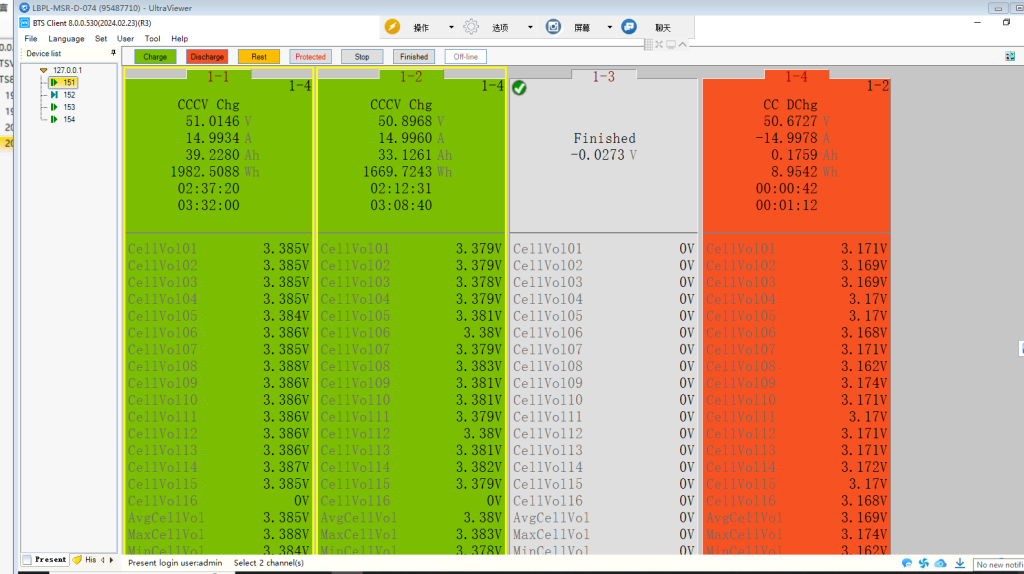

Communication allows the device to communicate with the BMS (Battery Management System) in your battery. Once communication is established, the test page will display information such as the cell voltage. You can view the cell voltage information and then configure your software. For example, you can set the test to end when the cell voltage reaches 3.65V or trigger an alarm if the cell voltage is abnormal. The data obtained through communication from the BMS will be saved and will be in “Record” page. After setting, the channels will look like this:

CAN and RS485 are both widely used industrial communication protocols (rules for data exchange between devices), but they differ in design, use cases, and performance. Here’s a clear breakdown:

1. CAN (Controller Area Network)

Core Definition

CAN is a differential, multi-master serial communication bus originally developed for automotive applications (to connect ECUs, sensors, actuators) but now used in industrial automation, robotics, and aerospace. It prioritizes reliable, real-time data transmission in harsh environments.

Key Features

Multi-master architecture: Any device on the bus can initiate communication (no single “master” controlling the bus), enabling flexible data exchange.

Message-based (not address-based): Data is sent as “messages” tagged with an ID (priority). Higher-priority IDs (e.g., emergency signals) preempt lower-priority ones—critical for real-time control.

Differential signaling: Uses two wires (CAN_H, CAN_L) to transmit signals differentially, reducing interference (noise) from electrical environments (e.g., engine bays, factories).

Error detection/correction: Built-in mechanisms (crc checks, bit monitoring) to detect corrupted data and retransmit—ensures high reliability.

Typical Use Cases

Automotive: Connecting engine control units (ECUs), ABS, airbags, infotainment systems.

Industrial: Robotics (e.g., collaborative robots), industrial controllers (PLCs), medical devices.

Core Definition

RS485 is a differential serial communication standard (not a full protocol—it defines physical layer specs: wiring, voltage levels, etc.) designed for long-distance, multi-drop communication. It’s often paired with protocols like Modbus, Profibus, or ASCII for data exchange.

Key Features

Differential signaling: Uses two wires (A, B) for differential transmission, enabling noise immunity and long distances (up to 1200 meters at lower baud rates).

Multi-drop capability: Supports up to 32 devices on a single bus (extendable to 256 with repeaters)—ideal for connecting multiple sensors/actuators to a master.

Master-slave architecture: Typically operates in master-slave mode (one master queries multiple slaves)—simple to implement but less flexible for real-time control.

Flexible baud rates: Adjustable speed (up to 10 Mbps at short distances), balancing speed and distance.

Typical Use Cases

Industrial automation: Connecting temperature sensors, pressure gauges, motor drives to a PLC (via Modbus RTU).

Building automation: HVAC systems, lighting controls, access control.

Energy systems: Solar inverters, battery management systems (BMS), smart meters.

- Q2: What is the purpose of the external equipment implementation tool, such as PLC, and what are its potential benefits?

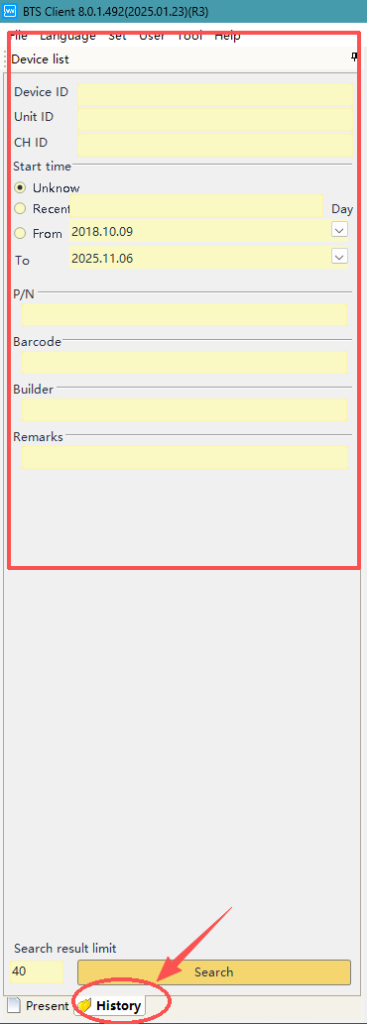

It can communicate with other brands temp chambers, cooling water machine, etc. The communication we have developed, or they can provide a communication protocol, can be used for connection. - Q3: How can I access recordings from a past date?

———————————–History and search - Q4: What functions do the Send BMS Data and Stop Sending BMS Data commands perform when you right-click on the channel in the Neware software?

Some BMS boards are special and require activation. Our software can send activation commands to the BMS, or send other commands you require to the BMS. - More posts you may interest in:

How to set up Neware BTS6000 battery module tester?

5-Minute Guide to Neware Battery Testing System Charge/Discharge Steps

5 Steps for Dry-Process Electrode Preparation

Coin cell or button battery assembly tutorial and common problem analysis