5 Minutes to Learn Sodium-ion Battery Testing: Electrical and Safety Performance

I. Sodium Ions (Na+)

A sodium ion is a sodium atom that carries a single positive charge due to the loss of one electron. Sodium ions play a vital role in both the natural world and biological life. For instance, they serve a critical function within cells, helping the human body maintain fluid-electrolyte balance and facilitate nerve impulse transmission and other physiological processes.

Beyond biology, sodium ions are widely utilized in industrial applications, such as the development of sodium-ion batteries and as electrolytes in lithium-ion batteries, demonstrating their broad technological significance.

II. Electrical Performance of Sodium-ion Batteries

Compared to lithium-ion batteries, research into the electrical performance of sodium-ion batteries is still in its early stages. However, current studies indicate that sodium ions possess higher electrochemical reaction kinetics than lithium ions and can operate effectively at higher temperatures.

As a result, sodium-ion batteries offer several distinct advantages, including:

Higher energy density potential in specific configurations.

Lower production costs due to the abundance of raw materials.

Superior environmental adaptability across various climates.

Despite these strengths, the cycle life of sodium-ion batteries requires further research and improvement to facilitate more widespread commercial adoption.

III. Safety Performance Testing for Sodium-ion Batteries

Safety performance testing is critical for the development of sodium-ion batteries. During the testing process, the battery’s physical, chemical, and electrical characteristics must be analyzed to evaluate its safety during both normal operation and extreme conditions (such as high temperatures, short circuits, overcharging, and over-discharging).

Below are the common safety performance tests conducted on these batteries:

Temperature Testing: Measures temperature fluctuations to evaluate the battery’s performance and stability under high-heat environments.

Thermal Runaway Testing: Simulates a single-cell failure within a battery pack to analyze thermal runaway characteristics, including the rate of temperature rise and maximum temperature limits.

Short Circuit Testing: Simulates internal short circuits to evaluate the battery’s durability and its specific response/protection mechanisms during a short circuit event.

Overcharge Testing: Subjects the battery to excessive voltage to assess its safety margins and performance stability when overcharged.

Heavy Impact Testing: Uses simulated mechanical impacts to evaluate the safety of the battery during both charging and discharging states.

These tests provide a comprehensive assessment of various safety parameters. The results help manufacturers and users understand specific battery limitations, allowing for optimized usage protocols, risk mitigation, and enhanced overall safety.

IV. Testing Landscape: Status Quo and Comparative Analysis

(1) Current Status

As an emerging energy storage technology, sodium-ion batteries (SIBs) are still in a relatively early stage regarding performance and safety research. Consequently, testing methodologies are continuously evolving.

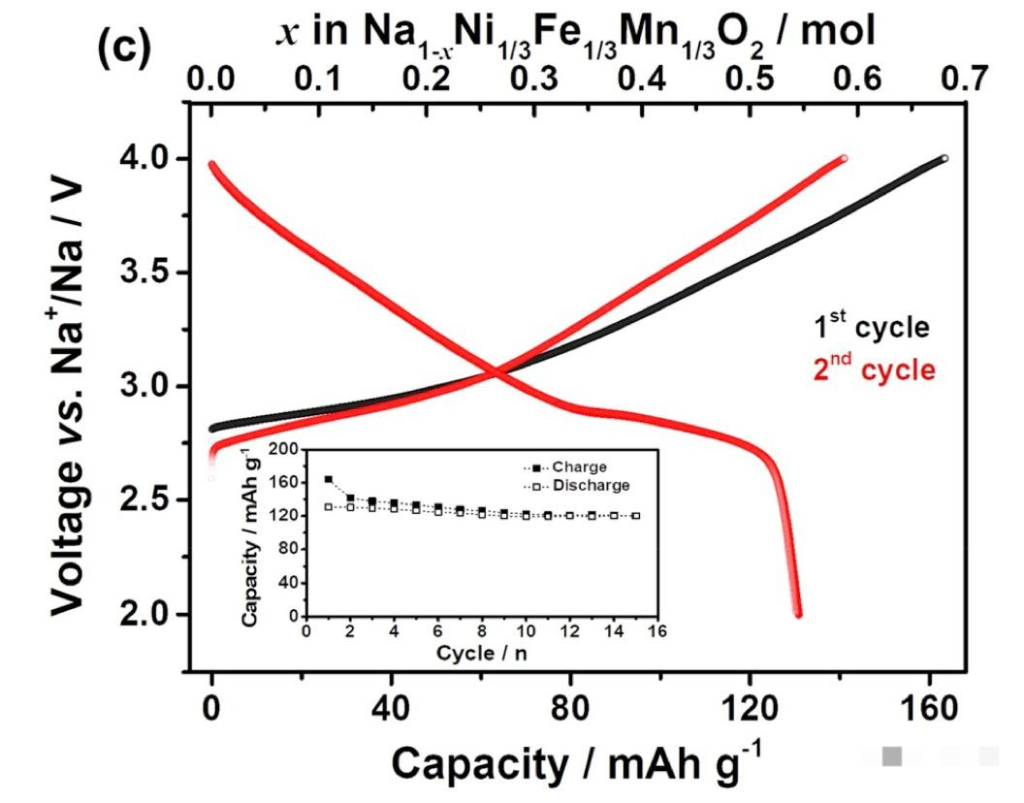

Electrical Testing Methods: Researchers worldwide primarily use Cyclic Voltammetry (CV), Galvanostatic Charge-Discharge (GCD), and Electrochemical Impedance Spectroscopy (EIS) to evaluate electrical performance.

Safety Testing Methods: Current safety protocols focus on thermal runaway, short circuits, overcharging, and mechanical impact to assess stability.

Research Progress: With the rapid acceleration of SIB research, high-performance cells have reached the laboratory-scale testing phase. Moving toward mass-market applications will require more refined testing to evaluate real-world feasibility.

Commercialization: While most products remain in the lab, market growth is driving SIBs toward practical use. They hold immense potential for grid energy storage and electric vehicles (EVs).

(2) Comparison: Sodium-ion vs. Lithium-ion Testing

While SIB testing methods are largely derived from lithium-ion battery (LIB) standards, significant differences exist due to their unique chemistries:

| Feature | Sodium-ion Battery (SIB) Testing Focus | Comparison to Lithium-ion (LIB) |

| Electrical Testing | Higher polarization potential during charge/discharge. | SIBs generally have lower conductivity than LIBs, requiring adjustments in current density during tests. |

| Safety Testing | Higher self-ignition temperature but higher sensitivity to overcharge/short circuits. | SIBs can be more prone to safety incidents under specific abuse conditions, shifting the focus of safety protocols. |

| Standards | Requires SIB-specific standards. | Standardized LIB protocols may lead to inaccurate results; dedicated industry standards are currently being developed. |

Summary

In essence, while SIB and LIB testing share a common foundation, SIBs require specialized protocols tailored to their specific chemical behavior. Establishing these unique standards is crucial to ensuring that test results are reliable, accurate, and reproducible.

(3) Future Outlook

As sodium-ion battery technology matures, its widespread commercial application is steadily becoming a reality. To ensure peak performance, reliability, and safety, we can expect the following advancements in testing technology:

Advanced Testing Methodologies: Future techniques will likely become more granular. This includes detailed analysis of internal structural changes and reaction kinetics, allowing for a more precise assessment of how the battery behaves under stress.

Refinement of Standards and Regulations: Due to the unique properties of sodium chemistry, testing standards must be further specialized. These regulations will need to be dynamically updated to keep pace with the rapid evolution of battery materials and their diverse applications.

Enhanced Data Management: As testing generates massive datasets, the future will see more advanced data storage and management systems. Utilizing AI and big data analytics will enable researchers and manufacturers to quickly retrieve and interpret critical performance metrics.

In summary, as sodium-ion batteries continue their rapid ascent, the methodologies for testing their electrical and safety performance will become increasingly sophisticated. This evolution will provide the robust technical foundation necessary for the next generation of energy storage solutions.

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.

Neware was founded in 1998. We are trusted by ATL, BYD, CATL, Tesla, Apple, HUAWEI, SolarEdge, etc. We provide battery testing solutions for testing battery cell, module, pack, supercapacitor, BESS, etc. If you want to do capacity, cycle life, pulse, DCIR, GITT, HPPC, or EV driving simulation test, please feel free to contact us.