- 7 most anticipated battery technologies in 2025, the first one is Sodium-ion batteries. Image source: CATLSodium-ion batteries hold great promise because they replace scarce lithium with abundant sodium, eliminating the need for cobalt and nickel. While the energy density of this chemistry still lags behind lithium-ion batteries, it offers a low-cost, non-flammable, and highly durable alternative.CATL’s recently launched sodium-ion battery (Naxtra) is a prime example of the industry’s high expectations. It retains 90% of its power at -40°C, boasts an impressive energy density of approximately 175 Wh/kg, and has a cycle life exceeding 10,000 charge-discharge cycles. Safety is a major selling point for CATL, as the battery demonstrated “no smoke, no fire” characteristics in abuse tests.

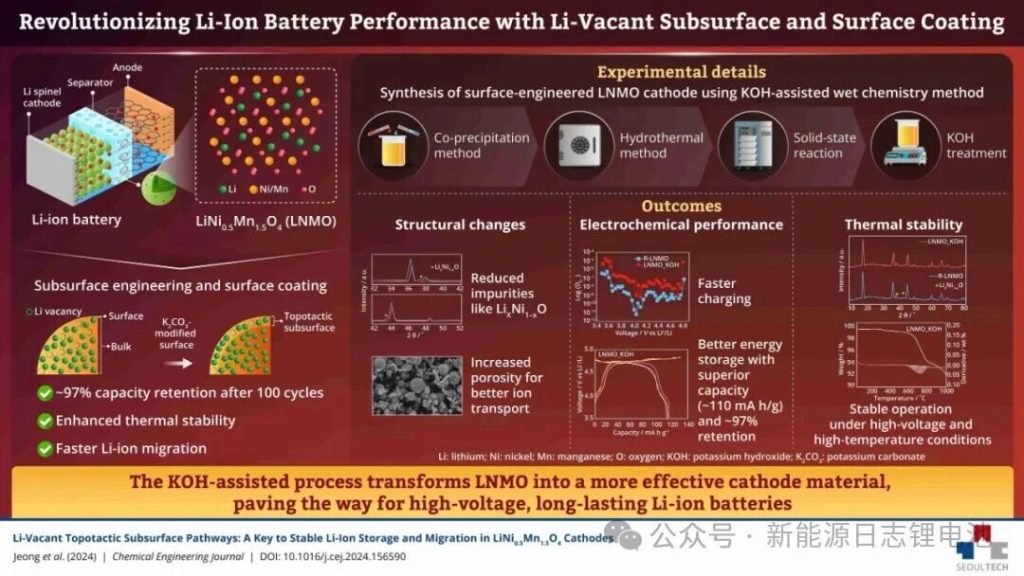

- LNMO (Lithium Nickel Manganese Spinel Oxide)Abstract of research findings from the research team at Seoul National University of Science and Technology, Dongwook Han.LNMO (lithium nickel manganese spinel oxide) is noteworthy because its cathode material, while containing nickel and manganese, eliminates the need for cobalt, which is extremely expensive and difficult to mine. Recently, engineers at Seoul National University of Science and Technology designed a lithium-vacancy-rich subsurface and a K₂CO₃-rich surface layer, thereby improving high-voltage performance and stability. The treated LNMO cathode material achieved a discharge specific capacity of approximately 110 mAh/g and a capacity retention of 97% after 100 cycles, outperforming untreated LNMO (89 mAh/g, 91% capacity retention). With such breakthroughs, LNMO is expected to achieve energy densities comparable to NMC (ternary lithium oxide) while maintaining costs and safety similar to LFP (lithium iron phosphate).

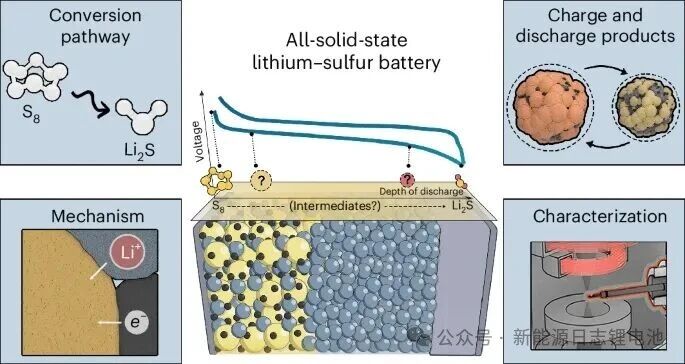

LNMO - Lithium-sulfur (Li-S) batteries use lithium metal as the negative electrode and sulfur as the positive electrode. Sulfur is abundant and inexpensive, and the chemical system requires no nickel, cobalt, or manganese. Lithium-sulfur batteries are also highly regarded for their theoretical energy density (approximately twice that of current lithium-ion batteries) and the enhanced safety due to sulfur’s non-flammability. However, challenges remain, including lower cycle life and energy efficiency caused by the “shuttle effect.”

- Solid-state batteries replace the flammable liquid electrolyte with solid materials. This change improves thermal stability and enables higher energy density because thicker lithium metal anodes and high-voltage cathodes can be used without triggering short circuits caused by dendrites. Recently, a series of announcements have brought solid-state batteries closer to reality. For example, Facitorial Energy released a polymer-based FEST battery that promises 25% more range than existing lithium-ion battery packs; while Toyota released a sulfide-based solid-state battery prototype aiming for a range of 621 miles (approximately 1000 kilometers) and a 10-minute charging time. Industry leaders predict that commercially available solid-state batteries will be available in the latter five years of this decade, with earlier semi-solid-state products appearing even sooner.

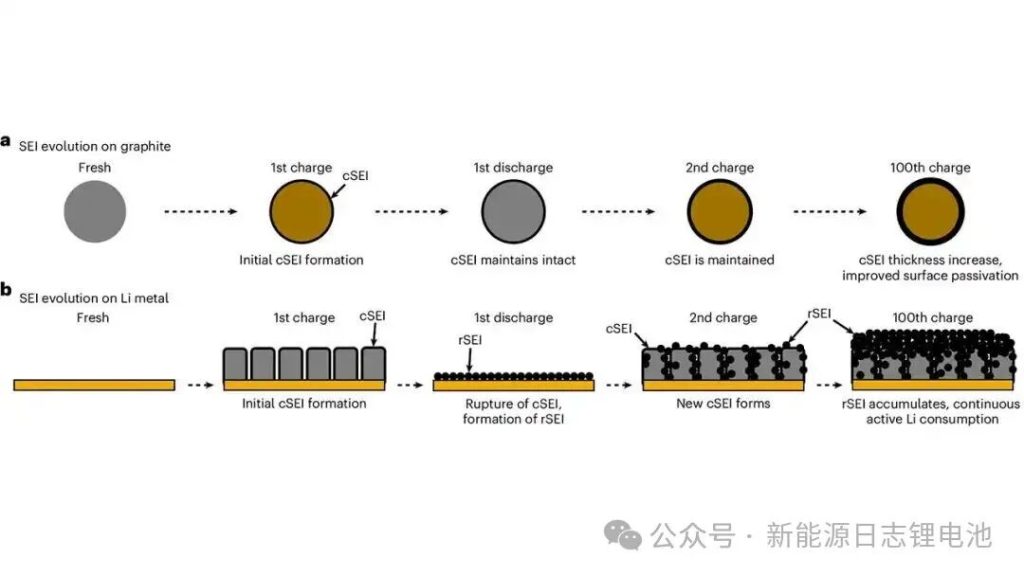

Solid-state batteries - Lithium-metal batteries use pure lithium metal to replace the graphite anode to achieve a theoretical energy density exceeding 500 Wh/kg. Historically, the main obstacle to this chemical system has been the growth of lithium dendrites, which can puncture the separator and cause short circuits. CATL recently used quantitative mapping technology to demonstrate that electrolyte salt consumption, not just dendrite growth, is the primary failure mechanism. Based on this discovery, CATL optimized the electrolyte composition, doubling the cycle life of its batteries.

Lithium-metal batteries - LFP batteries use lithium iron phosphate as the cathode material. Unlike NMC and NCA batteries, they contain no cobalt or nickel, making them cost-effective and environmentally friendly. Simultaneously, their robust molecular structure gives them high thermal stability and a long cycle life, ranging from 2,000 to 5,000 cycles, and retaining 80% of their capacity after 2,000 cycles. Due to their ability to withstand high-rate charging and discharging, LFP batteries are ideal for high-cycle applications such as engineering machinery and passenger electric vehicles.

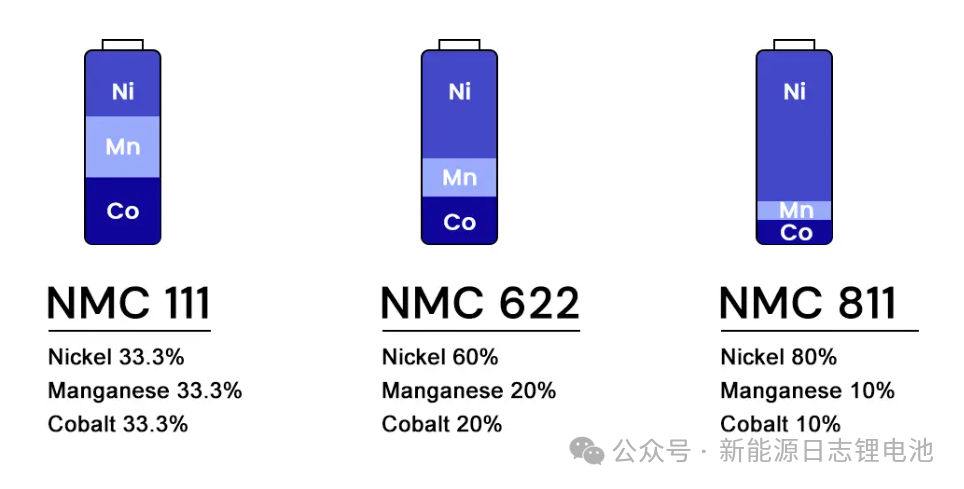

- NMC batteries use a layered cathode structure made of nickel, manganese, and cobalt. Their energy density, lifespan, and cost can be adjusted by changing the nickel-cobalt ratio. High-nickel models offer advantages in energy density and driving range but require meticulous thermal management; while balanced NMC formulations strike a trade-off between performance and stability. Their main drawback is their reliance on cobalt and nickel, which raises supply chain and ethical concerns.

NMC Source: WeChat https://mp.weixin.qq.com/s/Z7CPJ41NEMUwt-KlbcFcoA

If you do battery research or battery materials research, you might be interested in : Neware battery cyclers