Analysis of the causes of low voltage failure in lithium battery formation process and its impact on battery cells

Introduction: Low voltage failure during the lithium battery formation process is a common and significant issue. This typically indicates an abnormality during the initial charge and activation process.

I. Analysis of the Main Causes of Low Voltage Failure

First, raw material defects or poor quality incoming materials are a key cause. Active material defects, poor conductivity, or uneven coating in the negative electrode material can directly hinder lithium insertion and lead to excessive lithium ion consumption. Abnormal separator porosity, uneven thickness, or poor lyophilicity can impair electrolyte wetting and ion transport. Insufficient electrolyte volume, improper composition, or excessive impurities can trigger side reactions and consume active lithium. Positive electrode material defects, excessive residual alkali, and current collector contamination and oxidation are also serious issues. Furthermore, uneven dispersion or poor performance of auxiliary materials such as binders and conductive agents can also pose potential risks.

Second, defects in the battery cell manufacturing process are equally critical. Lamination/winding issues such as misaligned electrode plates and uneven winding can cause localized lithium deposition or short circuits. Cold or false welds during welding can lead to excessive contact resistance. Insufficient injection volume, inadequate wetting, or poor environmental control can create “dry areas” within the cell, preventing effective ion conduction. Poor packaging seals can cause electrolyte leakage or the ingress of external contaminants. Inadequate cleanliness control can easily introduce metallic foreign matter and dust, leading to micro-short circuits.

Improper formation process settings can also directly contribute to low voltage. Excessive charging current not only increases polarization but can also cause unstable SEI film formation and even lead to lithium deposition. Setting the charge cutoff voltage too low or inadequate constant voltage time prevents complete lithium ion intercalation. Temperature control that is too high or too low can affect ionic conductivity and the extent of side reactions. Insufficient rest time and improper process design can also interfere with adequate electrolyte wetting and reaction equilibrium.

Faults in the formation equipment or testing system itself should not be ignored. Hardware or software issues such as abnormalities in the formation cabinet channels, poor fixture contact, voltage detection errors, and program errors can all cause false low voltage conditions.

II. Impact of Low Voltage Faults on Battery Cells

Once a low voltage fault occurs, the battery cell has often suffered irreversible damage, severely impacting performance and safety. Its capacity will experience a significant and irreversible decrease, primarily due to irreversible consumption of active lithium and inadequate activation of the active materials. Cycle life will also be severely shortened due to factors such as continued thickening of the SEI film, deterioration of micro-shorts, and damage to the anode structure. Simultaneously, the cell’s self-discharge rate will significantly increase, increasing its internal resistance, which not only affects rate performance but also leads to increased heat generation during operation.

More seriously, safety risks will increase dramatically. Low-voltage faulty cells have a high risk of lithium plating. Lithium dendrites can pierce the separator, causing severe internal short circuits or even thermal runaway. Existing micro-shorts can expand during subsequent use, and increased gas production can cause the battery case to bulge or rupture. Furthermore, if these cells are mixed into the battery pack, they will become a weak link in the entire system, severely impacting the consistency, overall lifespan, and safety of the battery pack.

Low voltage failure during the formation stage is a key indicator of a serious cell defect or process abnormality. The root cause is irreversible consumption of active lithium (due to side reactions, lithium plating, and micro-shorts) and/or obstruction of lithium ion transport/intercalation pathways (due to poor wetting, poor contact, and material defects). Extremely serious consequences can lead to permanent capacity loss, a dramatic reduction in cycle life, high self-discharge, high internal resistance, and significant safety risks.

III. Summary

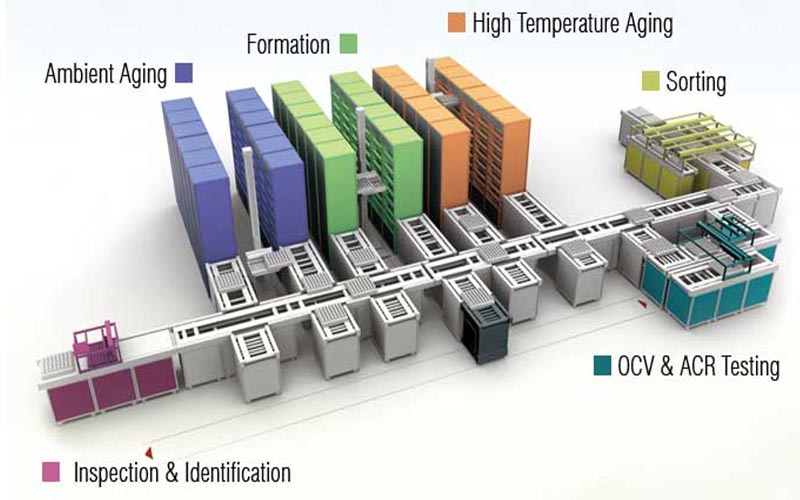

Therefore, monitoring and analyzing low voltage failure during formation is a crucial step in lithium battery production quality control, directly impacting the performance and safety of the final product. If the detection system is underdeveloped, these initial, weak voltage anomaly signals can be easily missed, effectively planting an undetectable “time bomb” in the battery. Selecting high-performance, high-precision battery testing equipment is no longer simply a production aid but a crucial line of defense.

Neware 4 Series battery testing system is designed for high-precision battery testing and supports research in a variety of application scenarios, including 3C batteries, solid-state batteries, and battery materials. Its four-range design offers measurement accuracy of ±0.05% F.S., meeting precision testing requirements from microamperes (μA) to milliamperes (mA).