Source: WeChat Official Account “Electric Vehicle Commune” 电动车公社

Hello everyone, I am the President of the Electric Vehicle Commune.

2025 can be described as a year of critical milestones for China’s new energy vehicles (NEVs).

According to statistics from the China Passenger Car Association (CPCA), the retail penetration rate of NEV passenger vehicles grew to 54% in 2025. This marks the first time it has surpassed the 50% threshold, setting a new historical record—a 6.4 percentage point increase compared to 47.6% in 2024.

This signifies that in the passenger vehicle sector, NEVs have become the primary choice for car buyers, while internal combustion engine (ICE) vehicles have officially become the “minority.”

Although NEVs have achieved a phased victory in the passenger sector, we must not forget that the automotive market consists of more than just passenger cars. Commercial vehicles—such as public buses, panel vans, and heavy-duty trucks—are equally vital components.

So, how did the electrification of commercial vehicles progress last year?

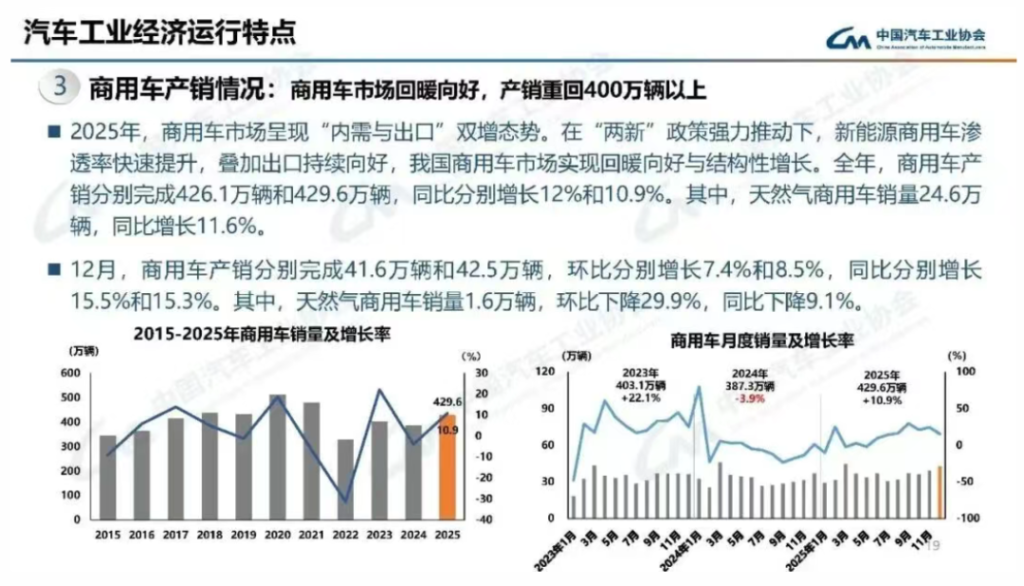

According to data from the China Association of Automobile Manufacturers (CAAM), sales of new energy commercial vehicles in China reached 871,000 units in 2025, accounting for 26.9% of total commercial vehicle sales.

Starting from the fourth quarter of last year, the penetration rate of new energy commercial vehicles began to show signs of a significant climb. From September to December, the monthly penetration rate rose for four consecutive months, jumping from 30% to 38.3%. However, even with this surge, the electrification process of commercial vehicles still lags significantly behind that of passenger vehicles.

Logically speaking, commercial vehicles are productivity tools designed to create wealth for their owners, much like taxis and ride-hailing cars.

Since they are “utility vehicles,” the lower the operating cost, the better. Every cent saved on fuel translates directly into cold, hard income.

It is precisely because electricity is significantly cheaper than oil in China that taxis and ride-hailing services have achieved such high rates of electrification across the country.

However, why hasn’t the commercial vehicle sector seen a massive surge in penetration driven by these low electrical costs?

To some extent, this is due to the insufficient “product strength” of current electric commercial vehicles, which prevents users from feeling confident and comfortable.

We are faced with a series of complex and severe challenges, including short driving ranges, slow charging speeds, low refueling efficiency, battery degradation due to temperature fluctuations, and poor resale value.

However, not long ago, someone in the industry began attempting to solve these problems.

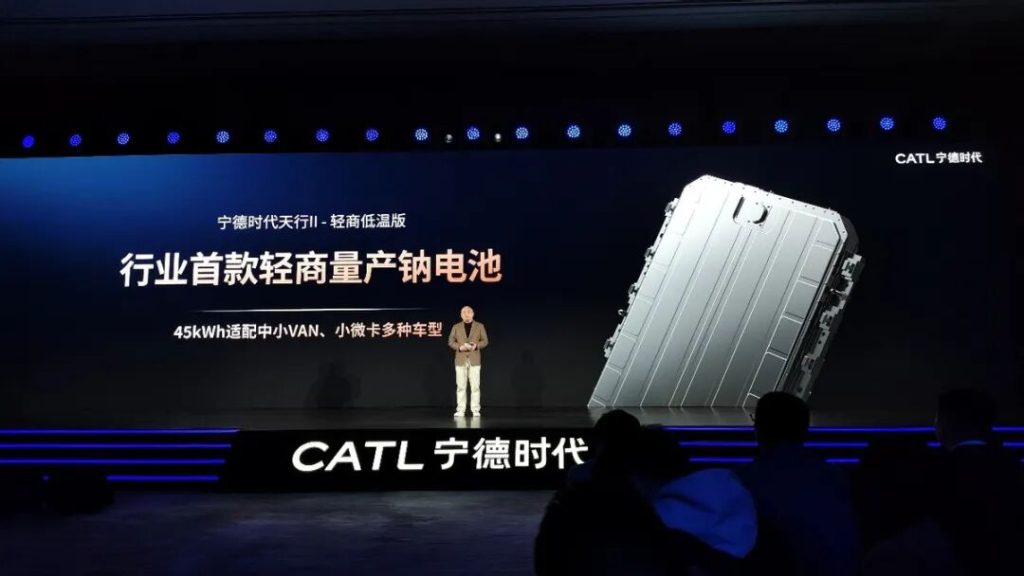

On January 22nd, CATL launched the “CATL TIANXING II Light Commercial All-Scenario Customized Series Solutions.” This release included a variety of battery solutions specifically designed for new energy light commercial vehicles, featuring technologies such as sodium-ion batteries, long-range capabilities, high/low-temperature supercharging, and battery swapping.

As CATL’s first major launch of 2026, it clearly demonstrates that the “Battery King” has elevated the importance of electrifying this specific market segment to a top-tier priority.

One key detail is that in this new battery launch, CATL did not attempt a “one-size-fits-all” approach to cover every vehicle model. Instead, they focused on extremely specific segments, such as urban distribution, intercity logistics, last-mile delivery, and low-temperature regions in the North. By precisely anchoring to these operational scenarios, CATL provided targeted battery solutions based on actual pain points, including delivery distance, charging requirements, and the total cost of ownership (TCO). This follows a logic of scenario-adapted customization.

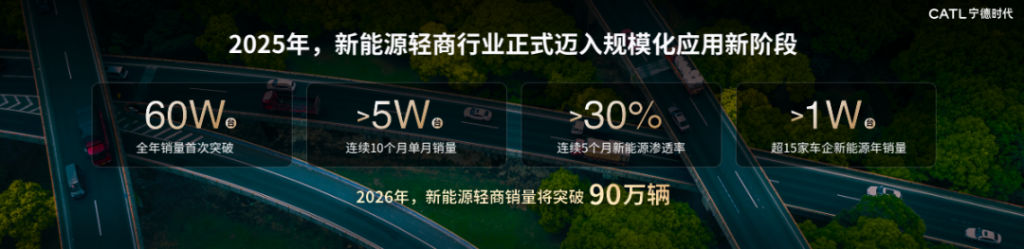

As for why CATL chose “light commercial vehicles” (LCV) as their breakthrough point? It is likely because LCVs represent the branch of commercial vehicles with the greatest potential for electrification. Over the past five months, the NEV penetration rate in this segment has consistently exceeded 30%, significantly higher than the industry average.

Let’s take this opportunity to see what specific new technologies/products CATL released this time, and what impact they will have on the market.

01. The Most “Freeze-Resistant” Battery in History!

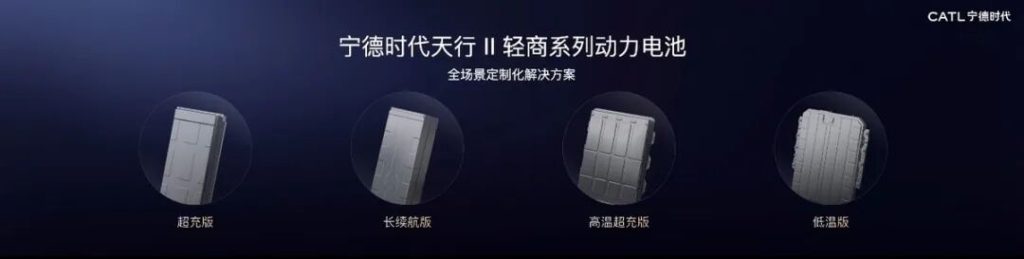

CATL’s newly released “Tianxing II Light Commercial Series” power battery comes in several different versions: a supercharging version, a long-range version, a high-temperature supercharging version, a low-temperature version, and a battery-swapping version.

Each battery has its own strengths, precisely addressing the inherent pain points of electrification in “light commercial” applications.

Let’s start with what I believe will have the biggest impact on the industry: the low-temperature battery.

The reason is that it’s not the lithium-ion battery used in the vast majority of cars on the market, but rather a sodium-ion battery.

It is common knowledge that lithium batteries—whether Lithium Iron Phosphate (LFP) or Ternary Lithium (NCM)—are terrified of the cold.

As soon as the ambient temperature drops below 0°C, the performance of lithium batteries declines significantly. Not only is the driving range severely compromised, but charging speeds also slow down to a crawl, making it difficult to even take a charge. Furthermore, discharge power is heavily restricted; in extreme cases, a vehicle might even struggle to climb a hill and start rolling backward.

To compensate for these low-temperature defects, the industry typically resorts to layering cells with self-heating PTC (Positive Temperature Coefficient) films to raise the battery temperature. However, we must not forget that heating the battery itself consumes additional power—it is essentially a workaround that treats the symptoms rather than the root cause.

This is why, even in 2026, the joke “Electric vehicles don’t cross the Shanhai Pass” (meaning they can’t handle Northern China’s winters) still persists.

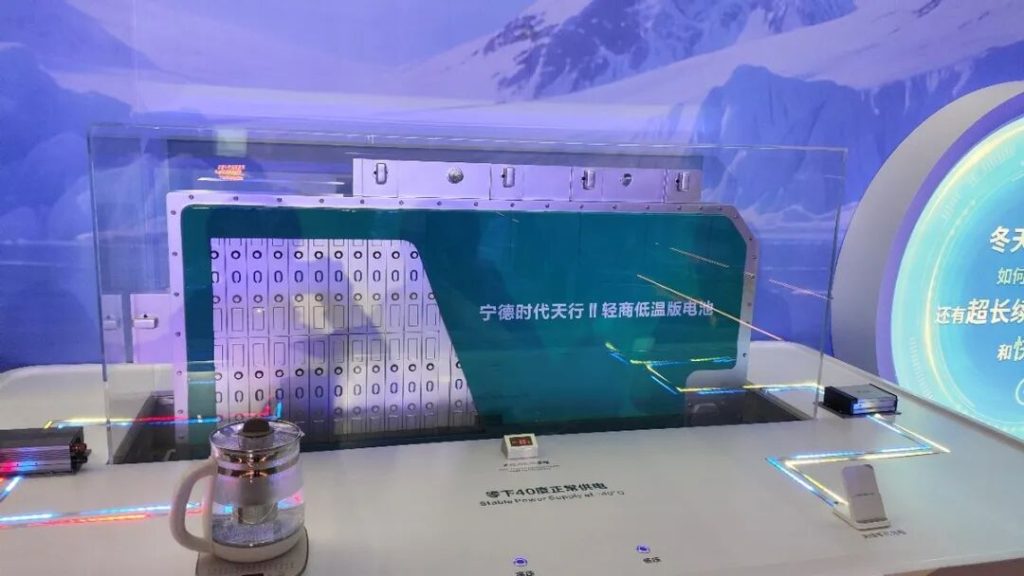

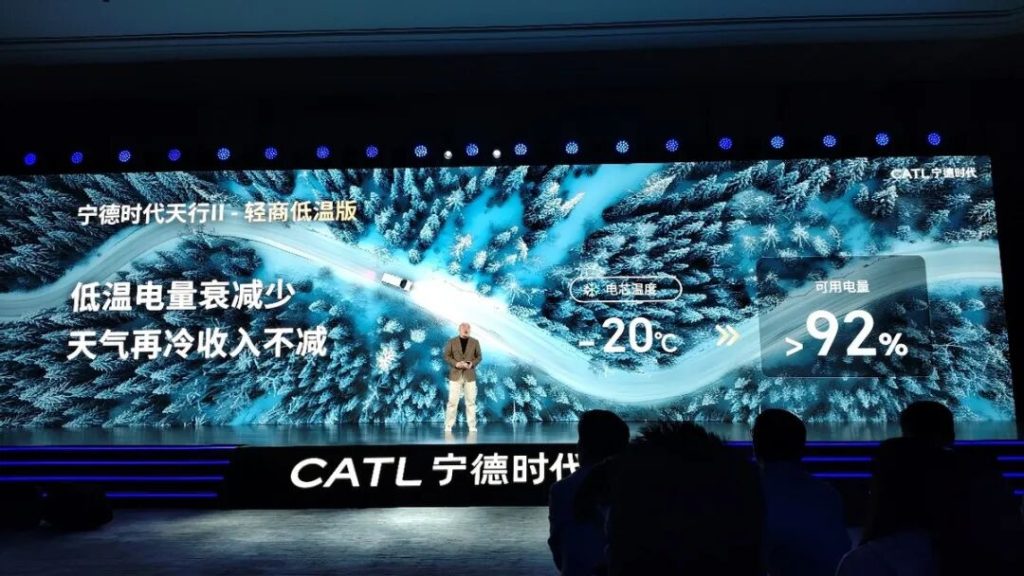

However, the “TIANXING II Low-Temperature Version” sodium-ion battery introduced by CATL this time offers performance that is a “dimensional strike” compared to traditional lithium batteries.

The specific performance data is remarkable: In a -20°C environment, even if the battery is frozen through to its core, its capacity retention remains above 92%. This means the displayed range on your dashboard will finally be a “real-world” number you can trust.

Furthermore, even if the temperature plummets to -30°C, you won’t encounter the dreaded scenario where the battery refuses to take a charge. At the same time, the vehicle can start instantly. Even with only 10% state-of-charge (SoC) remaining, the battery still provides enough power for a fully-loaded vehicle to climb a steep 10° incline.

So, why exactly can the low-temperature performance of sodium-ion batteries “crush” that of lithium-ion batteries? It all comes down to their inherent physical properties.

In traditional lithium-ion batteries, the electrolyte’s viscosity increases as the temperature drops. For lithium ions, which need to move at high speeds, this is like trying to switch from swimming in water to “swimming in wet cement”—movement becomes nearly impossible!

Sodium-ion batteries, however, are different. First, their electrolytes have a much lower freezing point, meaning they don’t become thick and sluggish even in extreme cold.

Furthermore, the ionic radius of a sodium ion is about 40% larger than that of a lithium ion, which actually makes it easier for them to break free from the “grip” of the electrolyte’s viscosity. Think of it like a crowded subway: a skinny person (the lithium ion) might get squeezed into a corner and lost in the crowd, but a larger, more robust person (the sodium ion) has the momentum to hold their ground and push through.

Beyond its outstanding cold-weather performance, the exceptional safety profile of sodium-ion batteries comes as a “pleasant surprise.”

Just how extreme is its safety?

While the vast majority of lithium batteries struggle to survive a single steel needle puncture test, a sodium-ion battery can be sliced through with an electric saw and still not emit smoke or catch fire. Incredibly, it can even continue to discharge power normally!

This implies that, in theory, once sodium-ion batteries are integrated into vehicles, they could allow for a reduction in peripheral components such as battery heaters and heavy-duty impact protection. This, in turn, reduces the hardware’s intrusion into the cabin, freeing up more space for passengers.

While sodium-ion batteries hold a clear advantage over lithium-ion batteries in terms of low-temperature performance and safety, they are not without their drawbacks.

For instance, the energy density of sodium-ion batteries is currently lower than that of Lithium Iron Phosphate (LFP). However, CATL’s engineers are currently utilizing a suite of technical solutions to bridge this energy density gap as much as possible. In the long run, sodium-ion technology has the potential to closely approach the energy density levels of traditional LFP batteries.

Furthermore, the cost of sodium-ion batteries remains slightly higher than lithium batteries for the time being, primarily because mass production has not yet reached full scale.

That said, with the CATL TIANXING II Low-Temperature Version becoming the first sodium-ion battery to pass national standard certification, its success in the commercial vehicle sector is expected to pave the way for its expansion into the passenger vehicle market. As production scales up, the inherent advantage of sodium—which is over 1,350 times more abundant in the Earth’s crust than lithium—will finally be realized, driving down the overall manufacturing costs of new energy vehicles.

02. The Era of “No Go Zones” for Electrification is Fast Approaching!

Now that we have covered the Low-Temperature Sodium-Ion battery, let’s take a quick look at the other battery types within the “TIANXING II Light Commercial Series.”

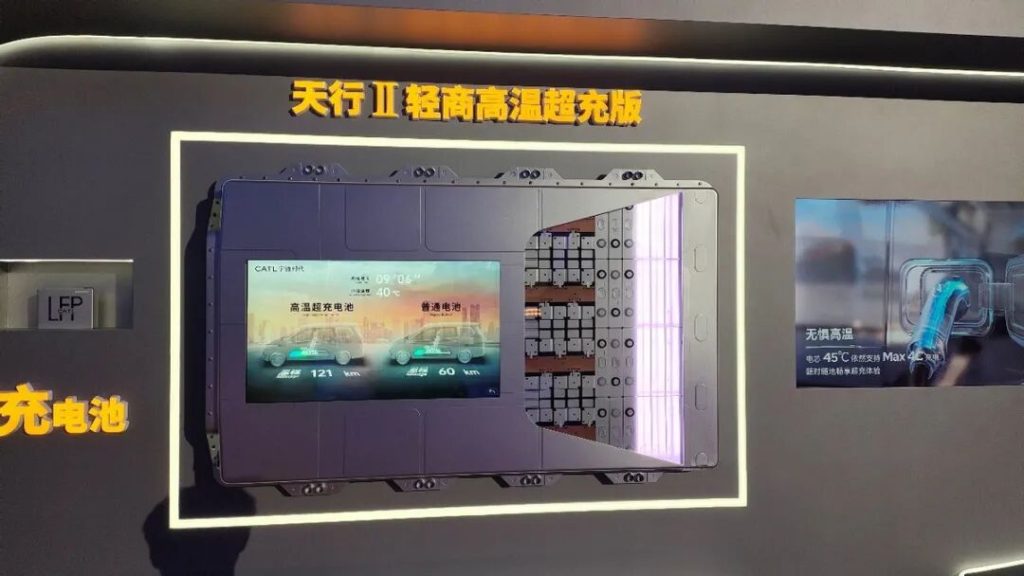

In reality, the strict environmental requirements for lithium batteries are not limited to extreme cold; high temperatures can be equally detrimental to their performance. To address this, CATL has also introduced a “High-Temperature Supercharging” version of the battery.

Its performance advantages are primarily seen in two areas:

First, its durability is industry-leading: at high temperatures of 45°C, the battery maintains a cycle life of 5,000 cycles, while at a standard 25°C, that figure exceeds a staggering 10,000 cycles.

Second, in terms of charging performance, it supports a peak rate of 4C. This allows for a 0–60% charge in just 18 minutes, effectively adding 10 kilometers of range for every single minute of charging.

What this means is that the combination of the High-Temperature Supercharging and Low-Temperature versions gives electric vehicles a much greater presence in extreme climates—whether it’s the 45°C heat of Turpan or the -40°C deep freeze of Yakeshi.

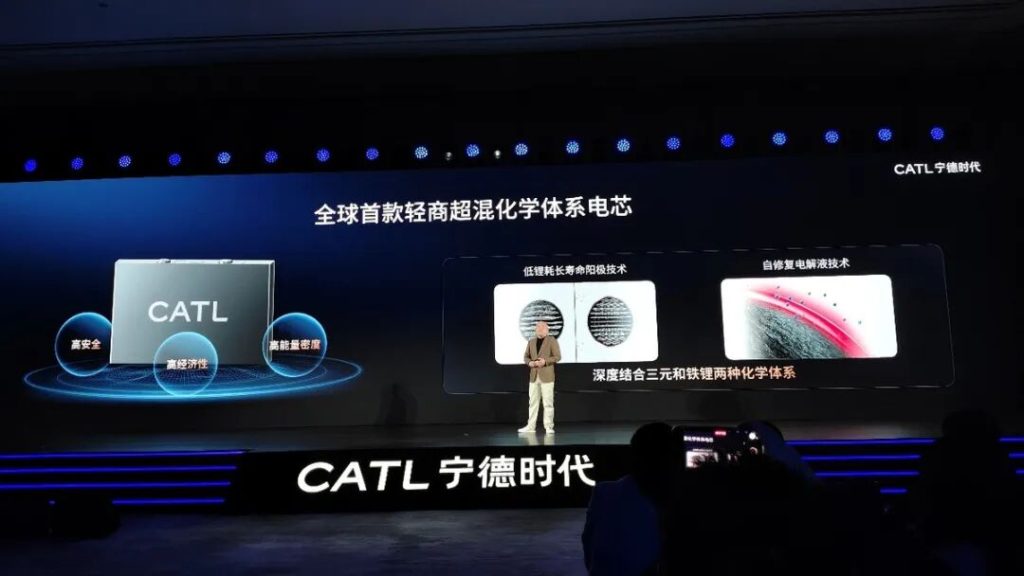

Finally, we have the “Long-Range” version. This is the world’s first power battery to integrate two distinct chemical systems: Ternary Lithium (NCM) and Lithium Iron Phosphate (LFP).

This version boasts two significant advantages: First is its massive capacity, with a single battery pack reaching 253 kWh. Second is its ultra-long range; according to CATL’s official real-world testing, it can achieve a driving range of up to 800 kilometers.

With this capability, a single charge is more than enough to handle long-haul transport routes of 600–700 kilometers. This eliminates the need for the specialized charging stops that were previously required mid-journey, significantly increasing the overall time-efficiency of logistics operations.

Clearly, the “Long-Range Light Commercial” battery is perfectly suited for long-haul, cross-province trunk logistics—scenarios characterized by a “drivers change, but the vehicle never stops” operational model.

On the other hand, the “Supercharging” version is specifically designed for short-haul urban distribution, catering to vehicles such as Lalamove (on-demand freight) and cold-chain box trucks.

These vehicles operate with much higher frequency, with average daily distances already reaching 200–300 kilometers. This places significantly higher demands on both charging efficiency and overall battery longevity.

Historically, however, Northern winters have caused batteries to frequently “drop the ball”—characterized by a sharp decline in discharge capacity, sluggish hill-climbing, and difficulty maintaining highway speeds. This has led to a “seasonal discount” on both urban distribution efficiency and driver income.

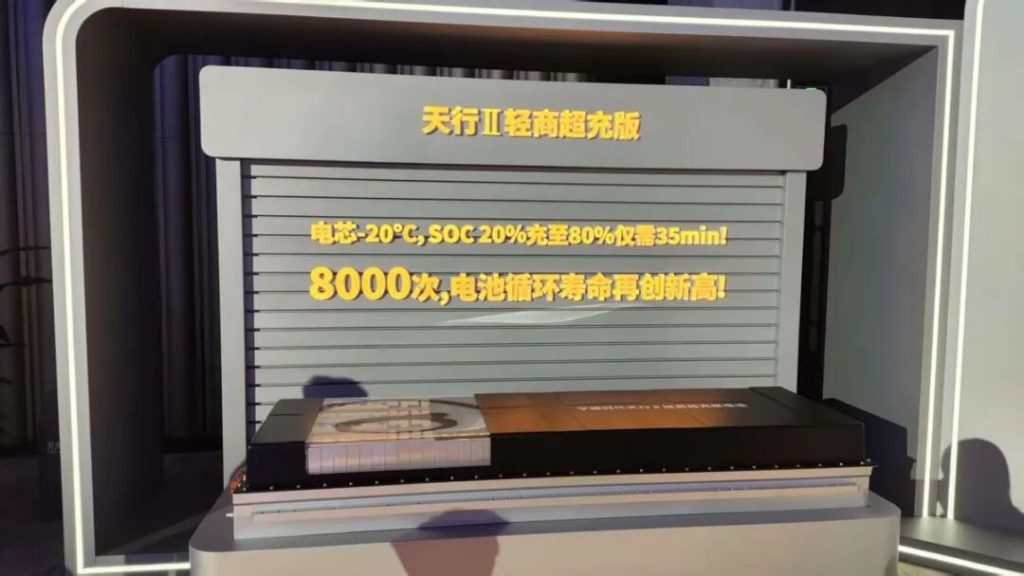

It is worth noting that the Supercharging version has undergone a systemic upgrade to address these specific issues. Despite utilizing a lithium-ion solution, it can still charge from 20% to 80% in just 30 minutes at -15°C. Furthermore, it allows the vehicle to maintain a steady 100 km/h even when fully loaded, and tackling a 15° incline is no longer a challenge.

In terms of durability, it achieves a cycle life of up to 8,000 cycles, far surpassing most batteries currently on the market.

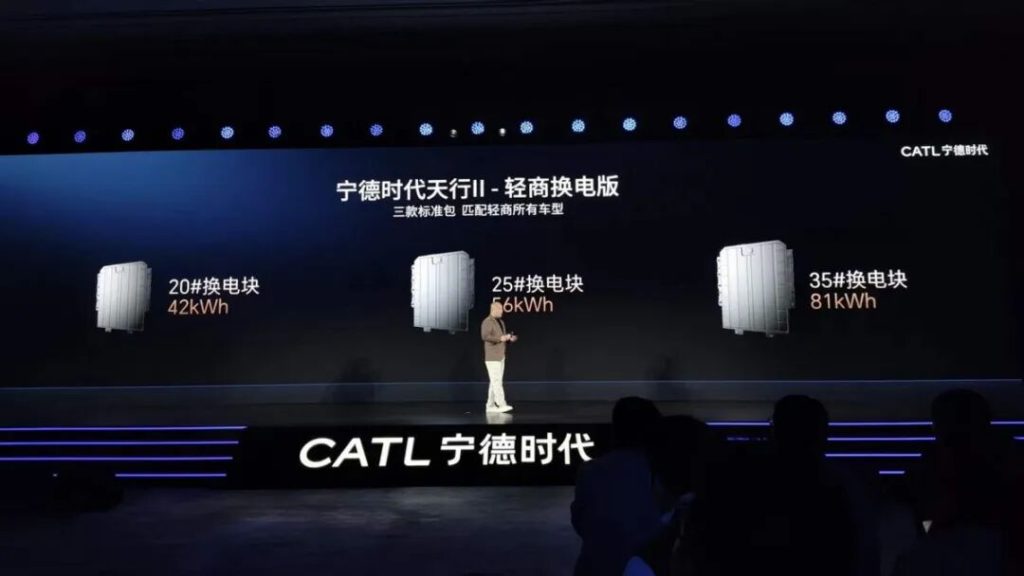

And for those who still find fast charging too slow, CATL has also introduced a “Battery Swap” version of the pack.

The battery packs are available in three optional specifications: 42kWh, 56kWh, and 81kWh. Not only are they compatible with the “Choco-SEB” (Chocolate) swap stations already deployed by CATL, but CATL also plans to invest in the construction of “Integrated Passenger-Commercial” super swap stations in the future.

More importantly, vehicle models equipped with the battery-swap version have the opportunity to utilize the “Vehicle-Battery Separation” model. This can lower vehicle purchase taxes and insurance premiums while simultaneously mitigating the issue of vehicle depreciation caused by battery degradation.

For the “light commercial” industry, the launch of the “Tianxing II Light Commercial Series” power battery heralds the imminent arrival of a nationwide “no-holds-barred” era of electrification in this niche market.

Once successfully promoted in the “light commercial” sector, the next step is to leverage this successful experience to expand into the entire commercial vehicle industry.

For CATL, this is a bold attempt to adapt to different needs within a niche market through different performance orientations, indicating the coming of an era of highly customized power batteries.

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.