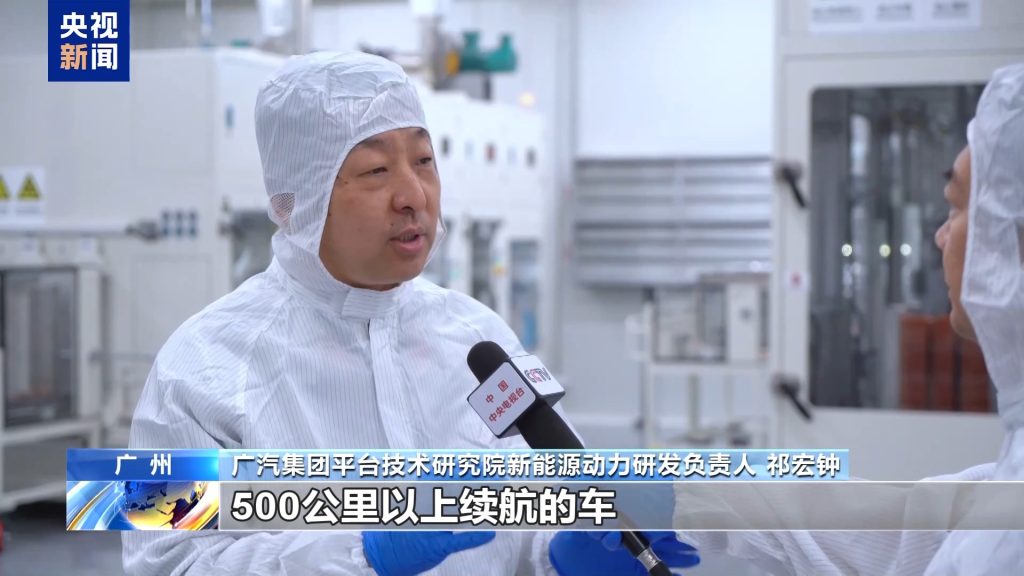

Recently, GAC Group‘s high-capacity all-solid-state battery production line, certified by CCTV, has generated significant excitement within the industry. What exactly constitutes the GAC solid-state battery architecture? The following content is compiled from publicly disclosed online information and is for reference only.

Primary Sources of Information:

1. April 12, 2024: 2024 GAC TECH DAY (GAC TECH DAY 2024), themed “Science and Technology Horizon.”

2. November 21, 2025: The 23rd Guangzhou International Automobile Exhibition (2025 Auto Guangzhou).

The GAC all-solid-state power battery leverages High Areal Capacity Solid-State Cathode Technology and the Third-Generation Sponge Silicon Anode Technology (a new nano-silicon composite anode). The all-solid-state electrode achieves an exceptional areal capacity of>5mAh/cm2, with a maximum reaching 7.7mAh/cm2. This translates to energy densities of>400Wh/kg and> 910Wh/L. Compared to the most advanced liquid lithium-ion batteries currently available, this represents an increase of over 50% in both volumetric and gravimetric energy densities, enabling a vehicle range exceeding 1,000km.

🔋 A. High Areal Capacity Solid-State Cathode Technology

This technology achieves its superior areal capacity ≥5mAh/cm2 through a three-fold breakthrough spanning cathode material, electrode design, and manufacturing process:

Cathode Material:

High-Stability Modification Technology: Includes a uniformly coated fast ion conductor layer on the surface, which effectively suppresses interfacial side reactions between the cathode material and the solid electrolyte, resulting in a 5% increase in thermal stability on the cathode side.

Precision Doping: Stabilizes the cathode material’s crystal structure and mitigates the risk of battery thermal runaway.

Electrode Design:

High-Permeability Lithium-Ion Transport Highway: The solid-state electrode achieves Li-ion conductivity comparable to liquid electrodes, even with 85% high active material loading.

Enhancements: Cathode thickness is increased by 40%, and the active material loading is boosted by 30%.

Manufacturing Process:

Dry Electrode Technology: Enables the solvent-free, highly efficient preparation of ultra-thick all-solid-state electrodes exceeding 250um.

🔋 B. Third-Generation Sponge Silicon Anode Technology

This technology employs a new nano-silicon composite anode material, delivering performance improvements across key metrics:

Gravimetric Capacity: Achieves 1,500mAh/g.

Swelling Rate: Reduced by 30%.

Cycling Stability: Improved by 135%.

Areal Capacity: Utilizes Dry Electrode Technology to achieve a maximum areal capacity of 7.7 mAh/cm2.

Mechanism Components:

Active Nano-Amorphous Silicon: Ensures structural integrity and optimized rate performance during cycling.

High-Strength 3D Support Matrix: Suppresses volume expansion and contraction during cycling, significantly enhancing stability in solid-state cells.

Fast Ion Conductor Coating: Improves the anode-solid electrolyte interface, facilitating efficient Li-ion intercalation and de-intercalation.

🔋 C. High-Strength Dense Composite Electrolyte Film

This proprietary solid electrolyte features high Li-ion conductivity, superior thermal stability, and ease of processing.

High Conductivity: Maximum conductivity reaches 10 mS/cm.

Ultra-High Safety: The solid-state cell remains functional after nail penetration and cutting, and can withstand 200 ℃ heat chamber testing.

Thermal Stability: The composite electrolyte film, based on a high-temperature resistant, non-flammable inorganic electrolyte scaffold, exhibits virtually zero thermal shrinkage at 200 ℃, mitigating flammability and thermal runaway risks.

Anti-Abuse Capability: Structural design significantly enhances the film’s anti-puncture strength, drastically alleviating damage from anode dendrites and mechanical abuse, thereby preventing internal short circuits.

🔋 D. GAC Patent on Sulfide Electrolyte Membrane

Patent Title: “Sulfide Electrolyte Membrane and its Preparation Method, Solid-State Battery” (Publication No. CN 119381534 A).

Application Date: November 2024.

Key Feature: The membrane comprises sequentially arranged First Electrolyte Layers (multiple sulfide inorganic electrolyte nanosheets, thickness<400nm and a Second Electrolyte Layer (sulfide inorganic electrolyte micrometer particles).

Benefit: This structure significantly improves the lithium-ion battery’s critical current density (CCD) and resistance to lithium dendrite growth.

🔋 E. Large-Capacity Cell Manufacturing Technology

GAC has achieved innovative breakthroughs in large-capacity cell process technology:

Process Innovations:

Ultra-thin electrolyte roll-to-roll film casting.

Composite assembly of the electrolyte film and electrode sheets.

In-situ interface fusion process.

Scale: Enables the manufacturing of large-sized, multi-layer stacked all-solid-state cells with a capacity of up to 60 Ah.

Cost Efficiency: Leads to a 15% reduction in equipment investment, a 40% reduction in plant area, and a 35% reduction in overall manufacturing cost.

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.

If you do battery research or battery materials research, you might be interested in these:

Battery testing equipment for cells