Comprehensive Characterization of Oxide Solid-State Electrolytes: From Powder to Interface

The research and development of oxide solid-state electrolytes (SSEs), such as LLZO and LATP, require a multi-dimensional approach. Unlike polymers, oxides are characterized by high rigidity, significant grain boundary resistance, and complex solid-solid interfaces. Consequently, characterization must focus heavily on microstructural density and interfacial chemical evolution.

Below is a detailed breakdown of the essential characterization techniques for membranes, powders, and full-cell systems.

1. Characterization of Membranes and Powder Materials

1.1 SEM and Cross-Sectional Analysis

Surface Morphology: Beyond assessing flatness, the focus is on grain boundary wettability. For oxide membranes, identifying “dead zones” or porous regions caused by incomplete sintering is critical.

Cross-Sectional Analysis: * Densification: Combined with the Archimedes method, SEM observes whether the fracture is transgranular or intergranular, indicating the strength of grain boundary bonding.

Pore Structure: Utilizing FIB (Focused Ion Beam) milling allows for smooth, damage-free cross-sections to observe nanometer-scale pores.

Lithium Compatibility: Post-cycling cross-sections reveal if lithium has penetrated the electrolyte through grain boundaries (grain boundary infiltration).

1.2 TEM, AC-TEM, and Mapping

Atomic-Level Grain Boundaries: The bottleneck of SSEs is often the grain boundary. Aberration-Corrected TEM (AC-TEM) can detect amorphous layers or impurities (e.g., AlPO4 in LATP) that hinder ion transport.

Elemental Mapping: This confirms whether dopants (e.g., Ta, Ga, Al) have successfully entered the crystal lattice or have segregated at the boundaries to form a “space charge layer.”

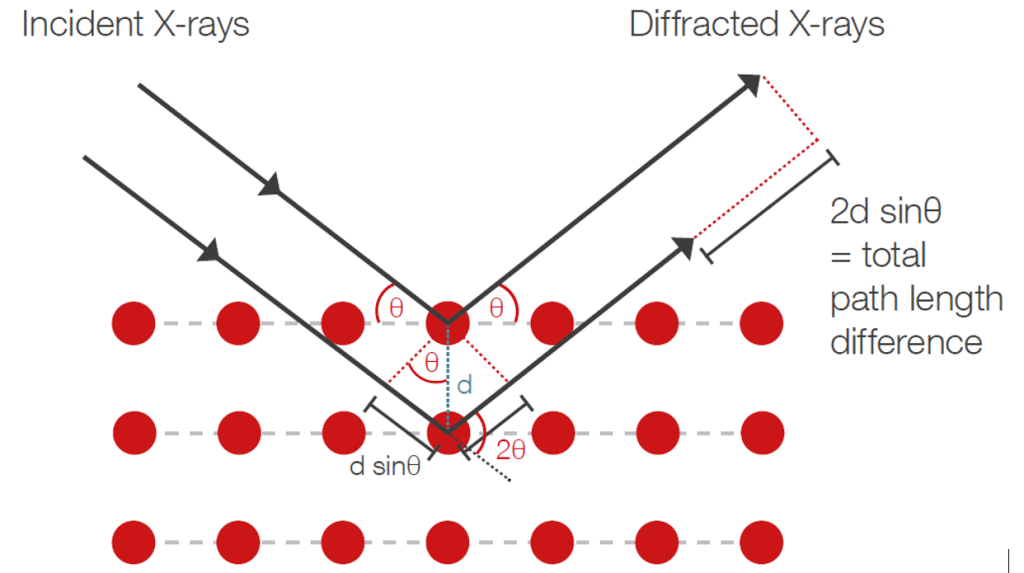

1.3 XRD (X-Ray Diffraction)

Rietveld Refinement: This provides precise lattice parameters (a, b, c). Changes in lattice volume caused by doping directly influence the activation energy for ion hopping.

In-situ XRD: Monitoring phase transitions during variable-temperature sintering helps prevent the formation of micro-cracks during the cooling process.

1.4 XPS and Defect Engineering

Valence States and Oxygen Vacancies: Focus is placed on the valence changes of dopants (e.g., Nb5+, Sb5+) and the resulting oxygen vacancies created to maintain charge neutrality.

Diffusion Mechanisms: Analyzing changes in bond strength (e.g., PO vs. PF) helps determine how the chemical environment promotes lithium-ion diffusion.

1.5 FT-IR and Raman Spectroscopy

Surface Carbonates: Oxides, particularly LLZO, react easily with moisture and CO2 to form Li2CO3. Raman is extremely sensitive to these surface layers, which are the primary cause of high Interfacial Area Specific Resistance (ASR).

Phase Identification: Raman can distinguish between cubic and tetragonal phases of LLZO with higher spatial resolution than XRD.

1.6 Solid-State NMR (ss-NMR)

7Li Nuclei:

Site Occupancy: Analyzes how lithium ions fill different sites (24d, 48g, 96h) within the lattice.

Diffusion Dynamics: Variable-temperature NMR measures relaxation times to calculate diffusion activation energy, proving the effectiveness of “fast ion channels” created by doping.

2. Interface Studies: Symmetric, Half, and Full Cells

2.1 Interfacial Evolution (XPS Depth Profiling & TOF-SIMS)

XPS Depth Profiling: Oxide electrolytes form reaction layers upon contact with lithium. Continuous etching maps the evolution of elements by depth, distinguishing between a stable SEI (e.g., LiF, Li3N) and an unstable interface (e.g., Ti4+rightarrow Ti3+ reduction).

TOF-SIMS: Provides high spatial resolution to generate 3D chemical maps of the SEI. It is particularly effective for capturing light elements like Li and H.

2.2 Observation of Lithium Dendrite Growth

In-situ Optical Microscopy: Captures real-time lithium dendrite nucleation and growth within cracks or along grain boundaries of the oxide electrolyte.

In-situ SEM: Observes the contact loss (void formation) and dendrite penetration at the Li/SSE interface under current-driven conditions.

2.3 Interface Contact and Stability (Ultrasonic & CT)

Ultrasonic Imaging: Physical contact in solid-solid interfaces is much harder to maintain than in polymers. Ultrasound non-destructively detects delamination, poor wetting, or gas evolution inside the cell.

X-ray CT (Computed Tomography): Provides a 3D view of the internal structural integrity, identifying micro-cracks in the ceramic pellet after extensive cycling. Cycle your batteries—–>Neware cyclers

2.4 Cathode/Electrolyte Interface (CEI)

Oxide-Specific Challenges: The contact resistance between an oxide SSE and oxide cathode particles is inherently high.

TEM-EELS: Used to analyze oxygen loss and elemental inter-diffusion at the cathode/SSE interface.

Coating Layers: Evaluates the effectiveness of buffer layers (e.g., LiNbO3) in suppressing interfacial side reactions.

Summary: Why Oxides Focus on Interfaces and Cross-Sections

Rigidity and Point Contact: Polymers act like “glue,” while oxides are “hard-on-hard.” Cross-sectional SEM is the only way to verify the effective physical contact area.

Dominant Grain Boundary Resistance: The total conductivity of an oxide is often limited by its boundaries. XPS etching and TEM mapping reveal the chemical makeup of these boundaries.

Environmental Instability: SSEs like LLZO are sensitive to ambient air. Research must prioritize surface characterization (Raman/XPS) to ensure surface contaminants are effectively removed before cell assembly.

Neware was founded in 1998. We are trusted by ATL, BYD, CATL, Tesla, Apple, HUAWEI, SolarEdge, etc. We provide battery testing solutions for testing battery cell, module, pack, supercapacitor, BESS, etc. If you want to do capacity, cycle life, pulse, DCIR, GITT, HPPC, or EV driving simulation test, please feel free to contact us.