Critical Current Density (CCD) Test Procedure Setup

Google Gemini’s answer is:

What is Critical Current Density (CCD) Testing?

In the field of solid-state batteries (SSBs), Critical Current Density (CCD) is one of the most vital metrics used to evaluate the performance of solid-state electrolytes (SSEs).

Simply put, CCD represents the maximum current density that a solid-state electrolyte can withstand before an internal short circuit occurs, typically caused by the penetration of lithium dendrites.

1. Why is CCD Critical?

While lithium dendrites are dangerous in liquid batteries, the liquid electrolyte is flexible. In solid-state batteries, it was originally hoped that the hard electrolyte would physically block dendrites. However, research has shown that lithium can grow along grain boundaries or through micro-cracks in the solid electrolyte, eventually piercing through and causing a catastrophic failure. The CCD value directly determines whether a solid-state battery can support fast charging.

2. Testing Procedure: Galvanostatic Cycling (Step-wise Method)

CCD is typically measured using a lithium metal symmetric cell (Li / Solid Electrolyte / Li) through a step-wise current increment method:

Cycling Setup: The battery undergoes repeated charge and discharge cycles (known as stripping and plating).

Current Increment: The test starts at a very low current density (e.g., 0.1 mA/cm2). The current is increased by a set amount (e.g., 0.1 mA/cm2) after every cycle or every few cycles.

Fixed Capacity/Time: Each half-cycle is usually set to a specific time (e.g., 0.5 or 1 hour) or a fixed capacity.

Voltage Monitoring: The voltage response is monitored in real-time as a function of time.

3. Identifying the End Point

The test continues until an anomaly in the voltage signal is observed. The signs of a short circuit (reaching the CCD limit) include:

Sudden Voltage Drop: The voltage abruptly drops to near 0V, indicating that a dendrite has bridged the anode and cathode.

Voltage Oscillation: The curve becomes irregular or “noisy” (sawtooth patterns), indicating micro-shorting or localized dielectric breakdown within the electrolyte.

The highest current density reached before this failure is recorded as the CCD of the material.

4. Factors Influencing CCD

Interfacial Contact: The tighter the physical contact between the lithium metal and the electrolyte (lower interfacial impedance), the higher the CCD.

Pressure: Increased stack pressure during testing often improves the CCD by maintaining contact.

Temperature: Higher temperatures typically improve ion transport and lithium plasticity, leading to a higher CCD.

Electrolyte Density: A denser electrolyte with fewer pores and defects is better at blocking dendrite growth.

5. Technical Terms Summary

Critical Current Density (CCD): The threshold current for short-circuiting.

Lithium Dendrite: Needle-like lithium structures that cause shorts.

Symmetric Cell: A cell with the same material for both electrodes (Li/Li).

Stripping and Plating: The movement of lithium ions back and forth.

Grain Boundary: The interface where crystals of different orientations meet in the electrolyte.

The following sharing comes from a friend who does battery materials research. Source: WeChat Official Account “Radish Master Brother” 萝卜大师兄 Lbdxs

Today I’ll share the procedure for setting the critical current density (CCD) using the Neware battery testing system. CCD is a standard test for studying solid-state electrolytes.

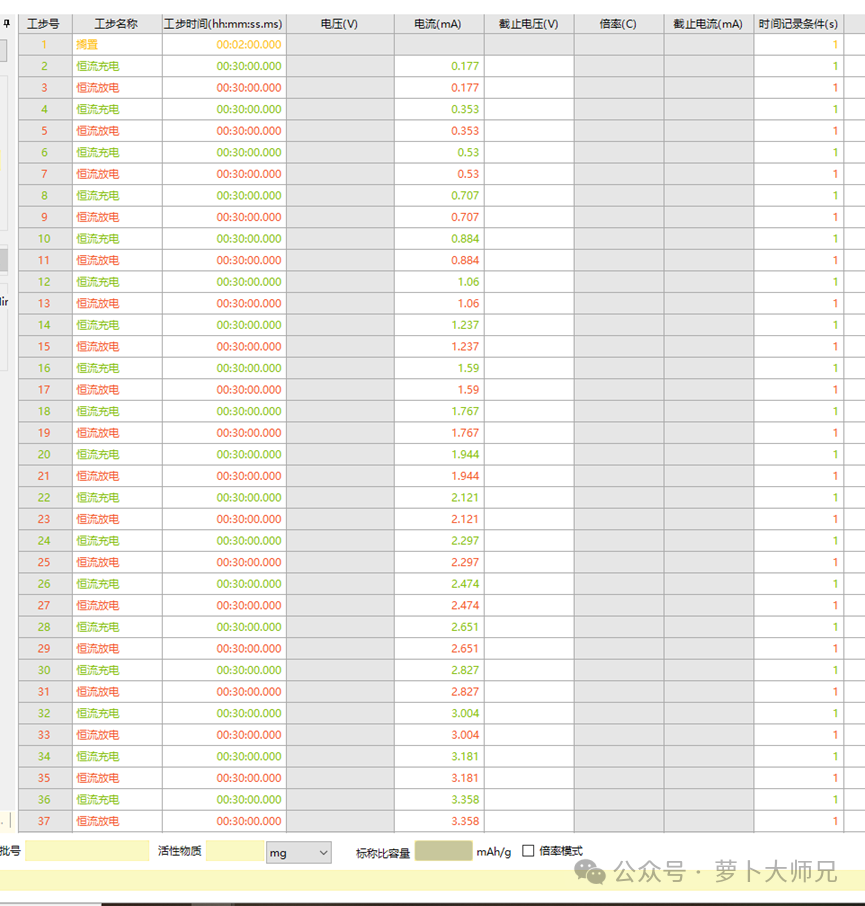

The setup is simple: start with 0.1 mA cm⁻² and run one cycle at each current density (the charge/discharge time can be set according to your needs, typically 30 minutes or 1 hour).

The current magnitude is calculated. For example, the 0.177 mA value is because the lithium chip we’re using has a diameter of 1.5 cm. The formula is: current density x lithium chip area = 0.1 x π x 0.75 x 0.75 = 0.177 mA. Subsequent current values are obtained using the same method.

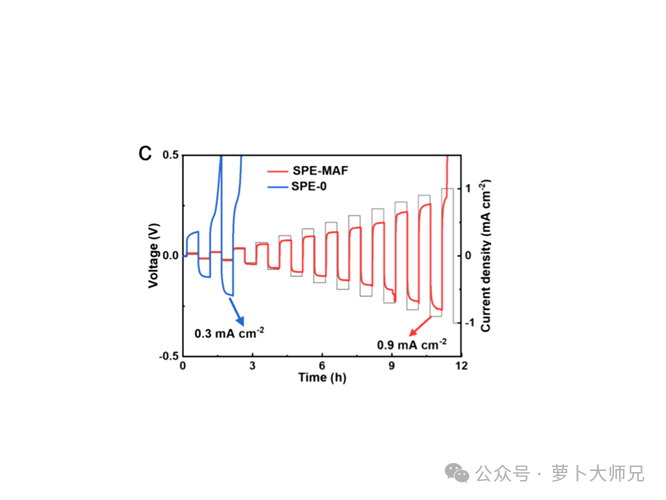

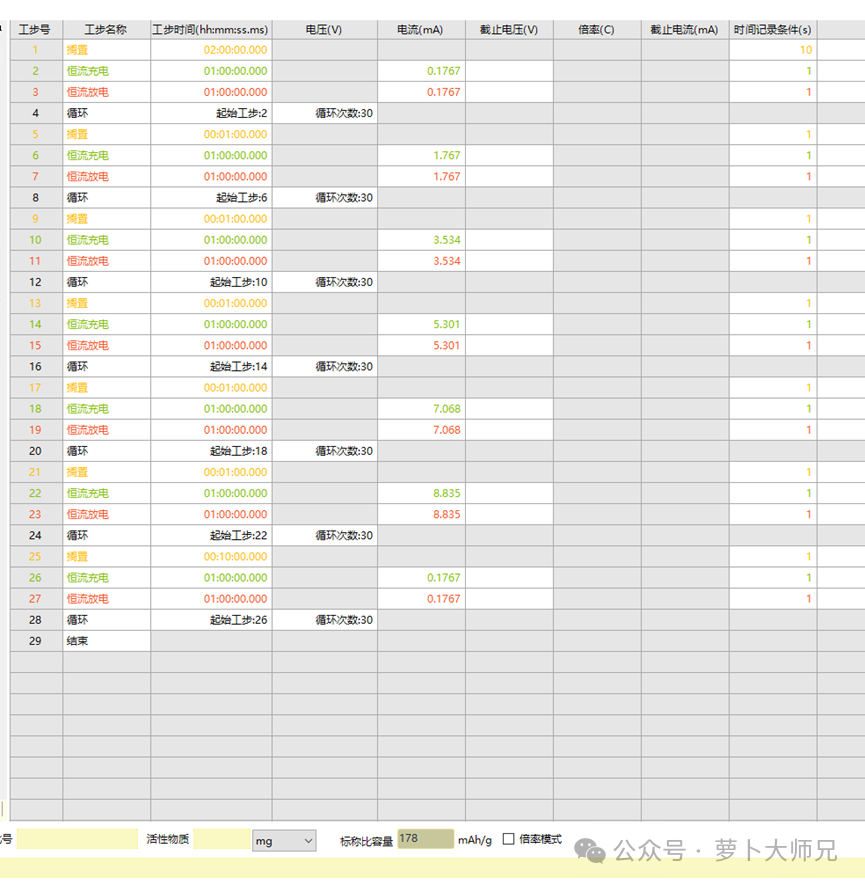

In academic papers, we often see tests similar to those used for full-electric cycle testing of lithium-ion symmetric batteries. These tests typically start at 0.1 mA cm⁻², progress to 2 mA cm⁻² or higher, and then return to 0.1 mA cm⁻². This is to demonstrate the compatibility between the solid-state electrolyte and the lithium-ion battery. However, the maximum current density measured in this test is generally higher than the current density measured by the CCD.

So, if a reviewer asks why your critical current density is only 1 mA cm⁻² but your test shows a reading of 2 mA cm⁻², how would you answer that?

Yellow is Rest 2 min. Green is constant current charging 30 min. Red is constant current discharge 30 min.

Current(mA) Time recording conditions(s)

Yellow is Rest 2 hours. Green is constant current charging 1 hour. Red is constant current discharge 1 hour. Black is cycle, The cycle starts from the previous constant current charging step and repeats 30 times.

Current(mA) Time recording conditions(s)

The information shared is for reference only. You will need to adjust the testing parameters based on your battery materials.

Due to the limited knowledge and English level is inevitable errors and omissions, if there are errors or infringement of the text, please contact me as soon as possible by private letter, I will immediately be corrected or deleted.