Ensuring Lithium-ion Battery Reliability: Safety Mechanisms and Failure Analysis in Extreme Environments

With the widespread adoption of lithium-ion batteries (LIBs), their safety performance under extreme conditions has become a focal point of industry concern. As the core component of new energy technologies, the reliability of LIBs is directly linked to the safety and efficiency of critical sectors, including electric vehicles (EVs) and energy storage systems (ESS).

I. Failure Mechanisms in Extreme Environments

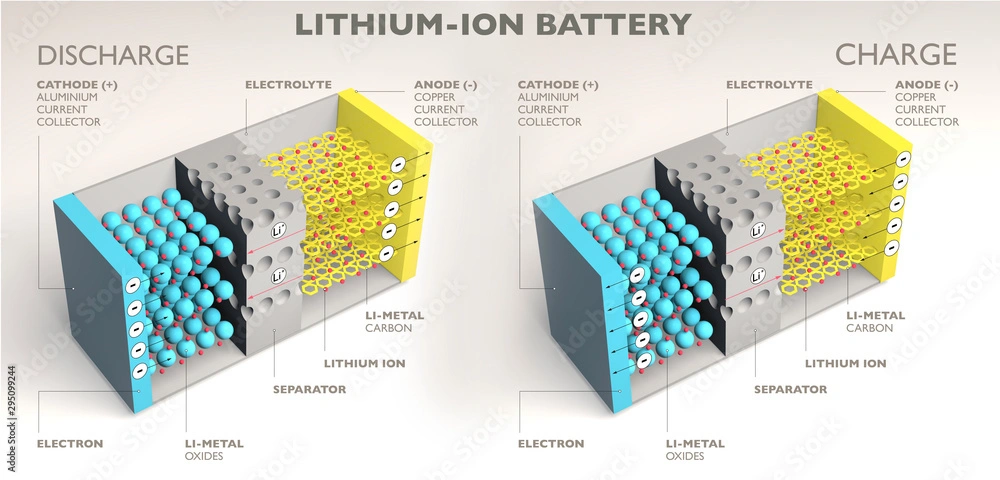

Lithium-ion batteries undergo complex electrochemical degradation when exposed to thermal extremes:

- Low-Temperature Environments (e.g., -40°C): At sub-zero temperatures, the electrolyte viscosity increases significantly, leading to higher ionic transport resistance and a sharp decline in discharge capacity. Concurrently, non-uniform lithium deposition occurs on the anode surface, inducing lithium dendrite growth. These dendrites risk puncturing the separator, potentially triggering an internal short circuit.

- High-Temperature Environments (>60°C): Elevated temperatures accelerate the decomposition of the Solid-Electrolyte Interphase (SEI) on the anode. This intensifies parasitic side reactions between the electrolyte and electrodes, generating gas and increasing internal cell pressure. If temperatures exceed 150°C, the separator undergoes thermal shrinkage or melting, leading to widespread internal short circuits. This ultimately triggers thermal runaway, accompanied by venting, fire, or even explosion.

- Thermal Shock (e.g., ΔT of 50°C): Rapid temperature fluctuations cause mechanical fracturing of active material particles and loss of interfacial contact. This results in a continuous increase in internal resistance (DCR) and accelerated capacity fade.

- High-Temperature & High-Humidity (85°C/85% RH): In environments with extreme humidity and heat, side reactions at the electrode interface are further catalyzed. This can trigger a chain reaction of thermal failure, leading to a “capacity plunge” and catastrophic consequences for the entire system.

II. Technical Core for Enhancing Reliability in Extreme Environments

1. Low-Temperature Technical Solutions

To combat performance degradation in cold climates, research focuses on optimizing ionic conductivity and interfacial kinetics:

- Electrolyte Anti-freezing: By employing a binary solvent system (e.g., FEC/EMC mixture) with a freezing point of -45°C, the discharge capacity retention at -30°C can be significantly improved from 35% to 65%.

- Anode Interface Engineering: Constructing a three-dimensional LiF@C composite layer on the surface of silicon-carbon (Si/C) anodes facilitates faster lithium-ion intercalation kinetics at low temperatures, reducing the overpotential that leads to lithium plating.

2. High-Temperature Protection Technologies

Managing thermal stability at the material level is crucial for preventing exothermic chain reactions:

- High-Temperature Electrolytes: The addition of Ethylene Sulfate (DTD) stabilizes the Solid-Electrolyte Interphase (SEI), effectively raising the thermal decomposition temperature from 150°C to 190°C.

- Cathode Coating Modification: Applying a 20nm-thick Li₃PO₄ nanocoating to the surface of NCM811 (LiNi₀.₈Mn₀.₁Co₀.₁O₂) cathodes inhibits the dissolution of transition metals (reducing the dissolution rate to <0.5%), thereby maintaining structural integrity under thermal stress.

3. Strategies for High-Humidity and Corrosive Environments

To ensure reliability in tropical or coastal climates, interfacial hydrophobicity and corrosion resistance are prioritized:

- Moisture-Resistant Electrolytes: Incorporating Trimethyl Phosphate (TMP) as a hydrophobic additive can reduce moisture permeability by more than 60%, mitigating the formation of harmful hydrofluoric acid (HF).

- Corrosion-Resistant Current Collectors: Utilizing Micro-Arc Oxidation (MAO) treatment on aluminum foil (forming a 3μm-thick protective film) ensures that the corrosion current density remains below 0.05 μA/cm² in hot and humid environments, preventing structural failure of the current collector.

III. Verification and Testing Protocols for Extreme Environments

To guarantee field reliability, lithium-ion cells and packs must undergo a rigorous validation matrix that simulates the most punishing operational conditions.

1. Cryogenic (Low-Temperature) Testing

These tests evaluate the battery’s ability to maintain power delivery and chemical stability in frigid conditions:

- Low-Temperature Discharge & Cold Start: Evaluates discharge efficiency and cranking power (simulating Cold Cranking Amps for EVs) at -30°C or -40°C, focusing on capacity retention.

- Low-Temperature Charging: Determines the safe charging envelopes (current/voltage limits) and assesses the risk of lithium plating at sub-zero temperatures.

- Low-Temperature Cycling: Continuous charge/discharge cycles at low temperatures to monitor impedance growth and accelerated degradation.

- Low-Temperature Storage: Assesses the capacity recovery rate once the battery returns to ambient temperature after prolonged exposure to cold.

2. Thermal (High-Temperature) Testing

High-temperature protocols are designed to assess thermal stability and aging kinetics:

- High-Temperature Discharge: Conducted at +60°C to +85°C to measure C-rate performance, discharge efficiency, and internal heat generation.

- High-Temperature Charging: Tests charge acceptance and the efficiency of the Battery Thermal Management System (BTMS) under thermal stress.

- High-Temperature Cycling: Accelerated life testing to identify aging mechanisms, such as electrolyte depletion and active material dissolution.

- High-Temperature Storage: Long-term storage (e.g., 7, 30, or 60 days) to monitor self-discharge rates, internal resistance (DCR) changes, and mechanical integrity (checking for swelling/gas evolution or leakage).

3. Thermal Shock and Temperature Cycling

These tests evaluate the battery’s structural resilience against rapid environmental shifts:

- Thermal Shock (Rapid Temperature Change): Cells are rapidly transitioned between extremes (e.g., -40°C ↔ +85°C) within minutes to inspect interfacial stability, seal integrity, and mechanical stress.

- Temperature Cycling: Slow, repeated cycles across a defined thermal range (e.g., -40°C to +85°C) to evaluate the impact of thermo-mechanical stress on internal components.

IV. Neware Advanced Battery Testing Solutions for Thermal Extremes

The Neware Environmental Test Chamber Series is engineered for high-precision temperature control, enabling engineers to simulate specific or extreme operating environments. These systems provide critical data support for R&D optimization by evaluating capacity retention, thermal stability, and safety cycle life under rigorous conditions.

- High-Precision Temperature Control: Features a temperature fluctuation of ≤0.5°C, ensuring superior stability and repeatability of test environments.

- Extreme Condition Simulation: Supports an ultra-wide temperature range from -70°C to 150°C, covering the most demanding aerospace and automotive testing standards.

- High Compatibility & Customization: Offers flexible configurations to tailor testing protocols based on specific battery chemistries and form factors (e.g., pouch, cylindrical, or prismatic cells).

- Intelligent Safety Features: Equipped with smart temperature regulation, automated fault alarms, and multi-tier safety interlocks to enhance laboratory efficiency and operational security.

Neware High-Low Temperature All-in-One System

The Neware All-in-One System is specifically engineered to provide precise environmental control and testing solutions for battery R&D and mass production. By seamlessly integrating high-performance battery charge-discharge testing modules with an environmental chamber, this system supports comprehensive battery characterization across a vast thermal spectrum.

- Advanced Hardware Integration: Merges cycling modules with environmental simulation (e.g., constant temperature, thermal extremes) into a single, compact footprint, significantly optimizing laboratory space utilization.

- Comprehensive Testing Suite: Supports a wide array of protocols, including Constant Current/Constant Voltage (CC-CV) cycling, capacity analysis, cycle life evaluation, and Direct Current Internal Resistance (DCIR) measurement.

- Unified Software Control: Features full integration with the BTS (Battery Testing System) host software, enabling synchronized operation and data management across multiple battery testing units.

- Multi-Zone Thermal Control: Offers a multi-zone architecture that allows for independent temperature regulation within a single system, catering to complex, concurrent testing requirements.

- Customizable Dynamic Ranges: Provides versatile voltage and current range options, tailor-made for diverse applications—from fundamental material research and 3C consumer electronics to high-power EV battery (traction battery) testing.