Title: Machine learning-guided discovery of ionic polymer electrolytes for lithium metal batteries

First author: Kai Li (Fudan University)

Corresponding author: Ying Wang (Fudan University)

NEWARE Supports Research on New-Type Ionomer Polymer Solid-State Electrolytes

Highlights of the article

In recent years, polymer solid-state electrolytes have received widespread attention in the field of high-energy-density lithium metal batteries. Various ion-conductive polymers with high electrical conductivity, electrochemical stability, and thermal stability have been developed. Among them, ionic liquids, as the basic components of ion-conductive polymer electrolytes, exhibit diverse types and complex selection criteria. Therefore, screening ionic liquids with high ion conductivity and a wide electrochemical window is crucial for achieving high safety and high energy density in lithium metal batteries.

Based on this, Ying Wang’s team from Fudan University has developed a machine learning approach that combines quantum chemical calculations and graph convolutional neural networks. From a pool of 2220 ionic liquids generated by the cross-combination of different anions and cations from the IoLiTec website, they efficiently screened ionic liquids that are liquid at room temperature and simultaneously possess high ion conductivity and a wide chemical stability window. If you need to control the temperature when testing batteries, click Neware BTS

They prepared a series of thin (~50 µm) and robust (>200 MPa) ion-conductive polymer electrolytes. The experimental results reported in this work once again demonstrate the advantages and feasibility of using rigid rod-like polymer electrolytes for the fabrication of all-solid-state lithium metal batteries. Moreover, this work provides new insights and research directions for overcoming data scarcity issues and effectively utilizing machine learning in material optimization. The research was published in the top international journal Nature Communications, with Kai Li as the first author of the paper.

Abstract

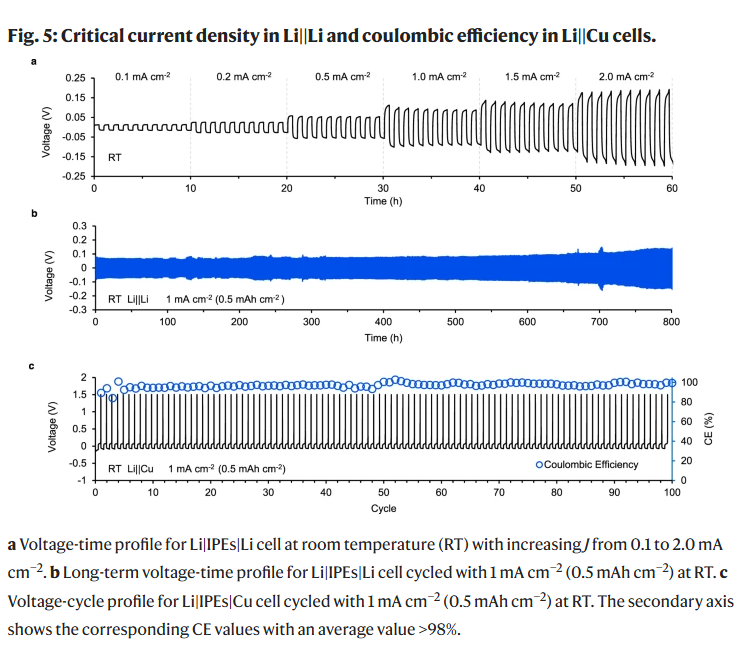

As essential components of ionic polymer electrolytes (IPEs), ionic liquids (ILs) with high ionic conductivity and wide electrochemical window are promising candidates to enable safe and high-energy-density lithium metal batteries (LMBs). Here, we describe a machine learning workflow embedded with quantum calculation and graph convolutional neural network to discover potential ILs for IPEs. By selecting subsets of the recommended ILs, combining with a rigid-rod polyelectrolyte and a lithium salt, we develop a series of thin (~50 μm) and robust (>200 MPa) IPE membranes. The Li|IPEs|Li cells exhibit ultrahigh critical-current-density (6 mA cm−2) at 80 °C. The Li|IPEs|LiFePO4 (10.3 mg cm−2) cells deliver outstanding capacity retention in 350 cycles (>96% at 0.5C; >80% at 2C), fast charge/discharge capability (146 mAh g−1 at 3C) and excellent efficiency (>99.92%). This performance is rarely reported by other single-layer polymer electrolytes without any flammable organics for LMBs.

Product citation

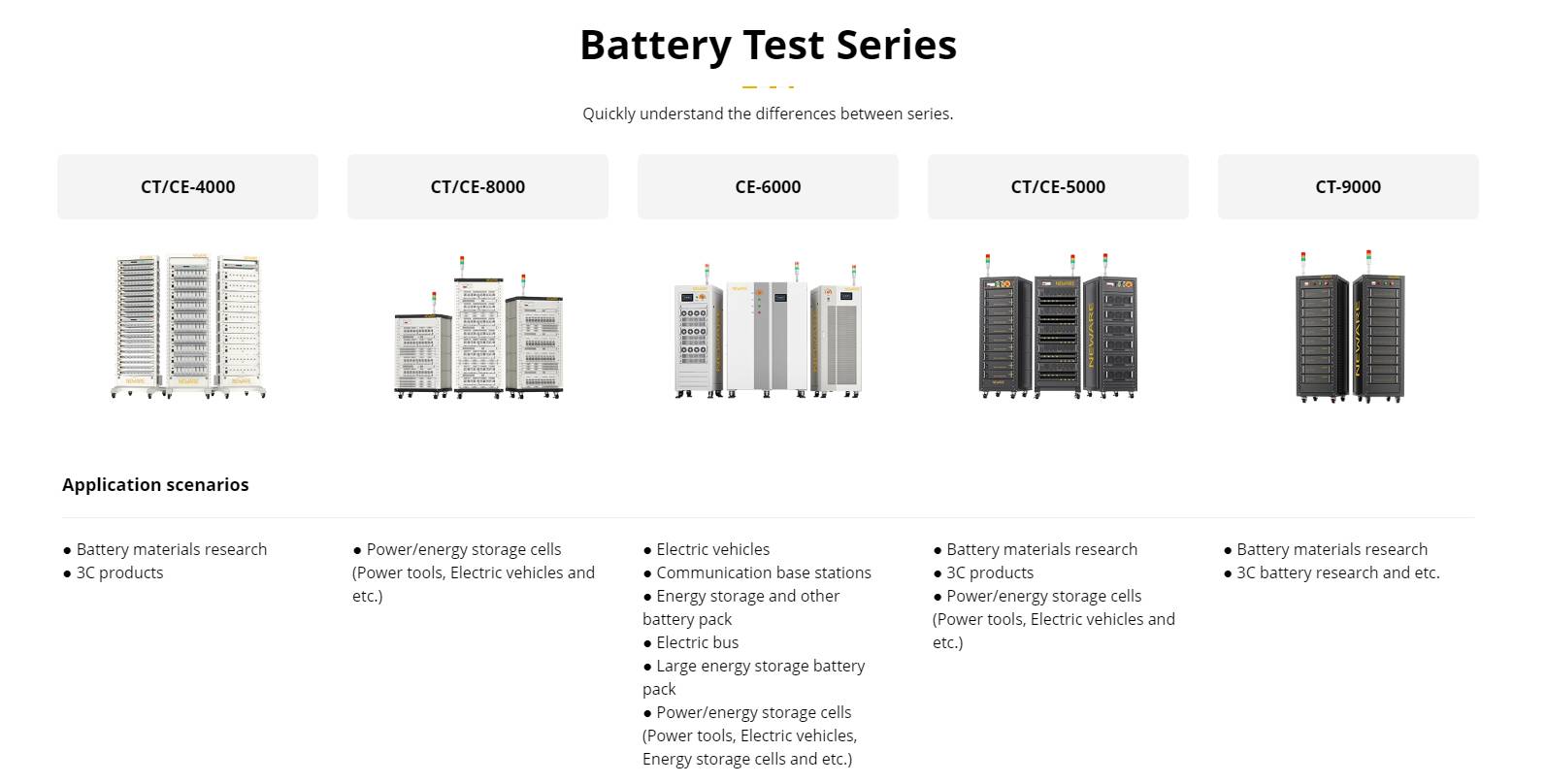

The article involves various electrochemical tests, and all the electrochemical performance was tested using battery testing equipment from NEWARE. In recent years, NEWARE has successfully developed a series of battery testing equipment with multiple channels, current ranges, and voltage ranges, effectively meeting the diverse testing needs of researchers.

NEWARE battery test equipments

NEWARE battery test equipment is tailored to meet various needs, featuring devices with a maximum sampling rate of 1000Hz, hardware response times from 500 microseconds to 20 milliseconds, a voltage range of 5V to 1000V, and a current range from 10mA to 1000A. It also offers the ability to test from a single channel up to 512 channels, accommodating a wide array of testing requirements.

NEWARE CT/CE-4000 series application scenarios: Research on battery materials and 3C products.

NEWARE CT/CE-5000 series application scenarios: Research on battery materials, 3C products, and power/energy storage cells (including power tools, electric vehicles, etc.)

NEWARE CE-6000 series application scenarios: Electric vehicles, communication base stations, energy storage, and other battery packs, electric buses, large energy storage battery packs, and power/energy storage cells (including power tools, electric vehicles, energy storage cells, etc.)

NEWARE CT/CE-8000 series application scenarios: Power/energy storage cells (including power tools, electric vehicles, etc.)

NEWARE CT-9000 series application scenarios: Research on battery materials, 3C battery research, and other related fields.

NEWARE

NEWARE, with over 25 years of battery testing experience, strives for innovative designs and superior quality. The company is dedicated to providing support for global battery manufacturers, electric vehicle producers, energy storage battery manufacturers, enterprises, national quality inspection departments, universities, and research institutions.

NEWARE offers high-performance battery testing systems, formation and grading systems, environmental test chambers, and automation equipment.

NEWARE provides system services such as NEWARE LabTech AI and NEWARE Store BI, as well as LIMS+MES.

NEWARE has a global service network, ensuring timely responses.

If you have any requirements or ideas regarding battery testing, please feel free to contact us. We are able to provide customized services based on your specific needs.