PITT test for Lithium-Sulfur batteries on Neware BTS 8.0

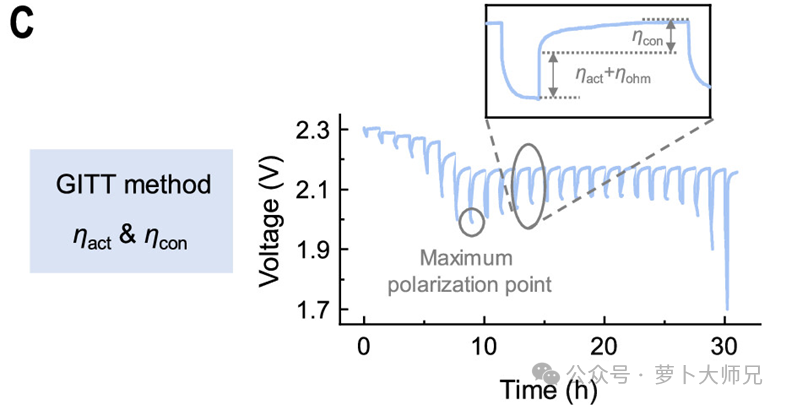

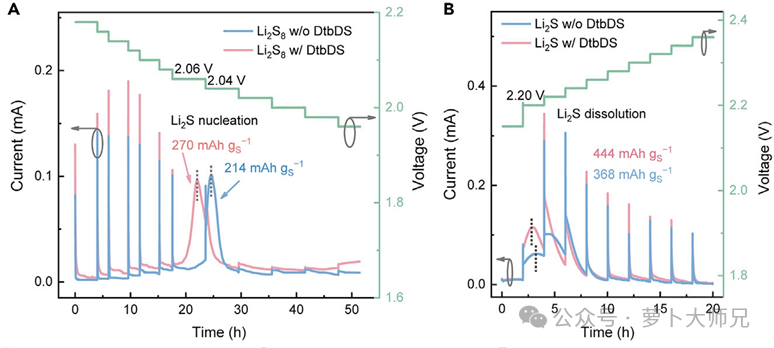

How to set up PITT test for Lithium-Sulfur batteries on Neware BTS 8.0? Basic Principles of PITT Test PITT requires the application of a series of small potential steps (typically 5 mV to 10 mV) to the battery. The voltage is held constant at each step until the current decays to a pre-set threshold. By recording the current-time curves (I vs. t), the diffusion coefficients of the Lithium-Sulfur battery can be calculated at different depths of discharge (DOD). Source: WeChat Official Account 萝卜大师兄 Lbdsx “Brother Radish” Today I’ll share the parameter settings for the PITT test of lithium-sulfur batteries (we’re using Neware battery cyclers). In the PITT test of lithium-sulfur