3 mins to know fast charging battery technology

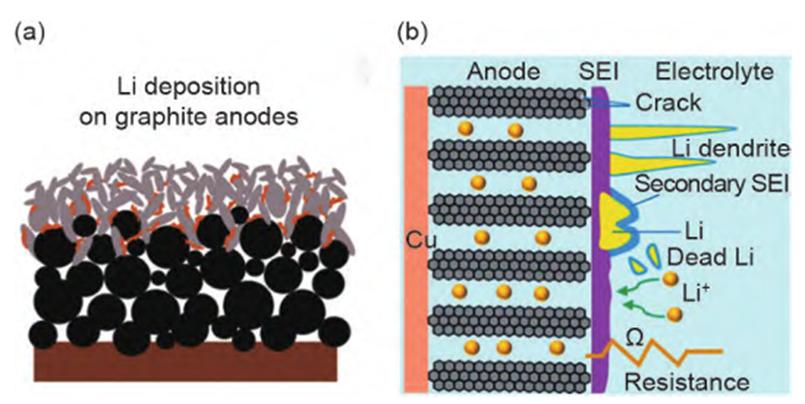

1.Research background and concept of fast charging battery With the introduction of the “double carbon” goal, a low-carbon trend in global energy and industrial development has emerged. Consequently, utilizing clean energy to power vehicles holds great significance in reducing CO2 emissions and achieving carbon neutrality. Electric vehicles powered by lithium-ion batteries have increasingly drawn attention due to their high energy density, long cycle life, low cost, and minimal environmental pollution. Nevertheless, despite projections that the global electric vehicle fleet will hit 230 million by 2030, both market penetration and consumer acceptance remain relatively low at present. One of the important reasons is mileage anxiety. Therefore, fast charging lithium-ion batteries have become